Imagine you had a favorite kitchen knife that you used every day. It is the perfect size, making vegetable prep a breeze. But over time, it starts to get dull, scratched, and worn down.

Now, what if there was a way to make it new again? Stronger, shinier, and resistant to damage?

We always assume metals last forever – but that’s not the case. Whether it’s tools, heavy machines, engines, or instrumental parts, they are all susceptible to wear and tear.

Take engine components as an example: over time, scratches, corrosion, or heat damage can cause them to underperform. That is where Stellite 6 laser cladding comes in.

Stellite 6 laser cladding is a high-tech solution that supercharges metals to make them withstand these harsh conditions. It’s a special alloy welded onto metal surfaces to create a corrosion-proof coating.

The result? Machines that last longer and work more efficiently.

How Does Stellite 6 Laser Cladding Work?

Stellite 6 is a superhero uniform for metal parts. It is a mix of cobalt, chromium, and several other elements that are essential for creating a coating around metal. This coating is resistant to wear and corrosion. It can also perform well in extreme heat, which is why it is used to strengthen industrial tools.

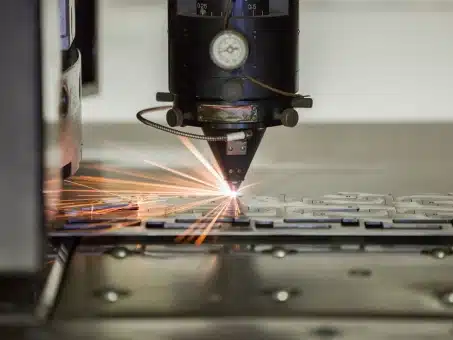

Stellite 6 can also be applied to repair metal parts when they sustain damage. This process is known as laser cladding, where a laser melts a thin layer of Stellite 6 over parts to create a coating—it’s like giving your tools a new suit of armor.

Engineers especially love the Stellite 6 laser cladding process for its speed and precision. The laser ensures the coating is precisely welded and applied at the right speed for full coverage.

Key Benefits of Stellite 6 Coatings

Metal parts are incredibly expensive, hard to replace, and costly to repair. But with the help of Stellite 6 coatings, you can create a superhero suit for your machines. Here are some of the key benefits of Stellite 6 laser cladding:

Wear Resistance

Laser cladding with Stellite 6 gives parts incredible strength, durability, and resilience. Whether it’s friction, pressure, or repeated use, Stellite 6 ensures that your machines withstand constant stress easily.

The result? Machines that resist damage, with metal surfaces that remain scratch-free and dent-free for years to come.

Corrosion Resistance

Metal parts, especially those exposed to water, chemicals, or environmental elements, can corrode and weaken. Using Stellite 6 allows us to form a protective surface over the metal to prevent rust and chemical damage.

This creates a layer that is not only heat-resistant but can also handle challenging environments without losing its strength and reliability.

Extended Life

Using a Stellite 6 coating on any metal or machine will extend its life, making it ideal for industrial parts. It is perfect for machines that tend to run longer and are expensive to replace.

Studies have shown that laser-clad equipment performs better and is used for much longer.

Microstructure and Performance

We’ve already explored what Stellite 6 laser cladding does for metal surfaces; now let’s look at how it does that. During the laser cladding process, Stellite 6 forms a unique pattern of crystal structures on the metal surface. As it cools, this becomes tough and scratch-resistant.

This hardened pattern is known as the microstructure of the laser-clad Stellite 6.

These crystals improve the hardness of the metal and prevent scratches and dents from forming. It also enhances adhesion, ensuring the coating bonds properly and retains its protective qualities.

Stellite 6’s microstructure is the reason why ordinary metal can turn into high-performance components. Its microscopic structure makes it highly resistant to wear, corrosion, and extreme conditions.

Industrial Applications

Stellite 6 laser cladding has many industrial applications. It is used across different industries to create a protective coating that ensures the smooth running of some of the most critical machines.

Here’s what that looks like:

Oil & Gas

In the world of oil and gas, Stellite 6 laser cladding ensures that metal withstands extreme heat, pressure, corrosive chemicals, and more. Valves, pumps, and other critical components are often laser-clad to ensure they last longer, perform reliably, and prevent costly downtime.

Aerospace

Airplane and spacecraft components are exposed to high temperatures and constant stress. Stellite 6 laser cladding can strengthen aircraft components. Whether it is turbine blades, engine parts, or landing gear, an additional coating helps maintain peak performance and meet safety standards.

Tooling & Machinery

Stellite 6 laser cladding can be used to extend the lifespan of cutting tools, molds, and other industrial equipment.

Explore FormAlloy’s Custom Laser Cladding Solutions

Whether it’s protecting industrial tools or strengthening high-performance machinery, Stellite 6 laser cladding is a game-changer. It has many industrial applications and enables engineers to build corrosion-resistant parts with extended lifespans.

Using advanced surface coating ensures that the component performs better, lasts longer, and minimizes costly downtime. That’s why FormAlloy’s custom Stellite 6 laser cladding solutions are trusted across oil & gas, aerospace, and manufacturing industries.

Our tailored solutions improve both productivity and performance by protecting critical components. If you’re interested in learning more about our equipment, contact FormAlloy today.

Frequently Asked Questions

- What is Stellite 6?

Stellite 6 is a cobalt-chromium alloy that is used for its exceptional hardness, wear resistance, and corrosion protection.

- What is laser cladding?

Laser cladding is a process of laser metal coating that strengthens metal surfaces for added protection.

- Why is Stellite 6 used for laser cladding?

Stellite 6 is heat-resistant, offers corrosion protection, and helps to extend the lifespan of industrial components.

- What industries use Stellite 6 laser cladding?

Stellite 6 is used in different industries such as oil, gas, aerospace, tooling, and machinery to strengthen components to withstand extreme conditions.

- How does laser cladding improve wear resistance?

Laser cladding improves wear resistance by tightly bonding metal surfaces to reduce friction and protect the metal from scratches and corrosion.

- Can Stellite 6 coatings prevent corrosion?

Yes, Stellite 6’s chemical composition helps metals resist environmental damage, extending their service life.

- What is dilution in laser cladding?

Dilution is the mixing of the coating with the base metal, which affects its protective properties.

- How long do laser-clad Stellite 6 coatings last?

When applied correctly, Stellite 6 coating can extend component lifespans and prepare them for demanding industrial use.

- Is laser cladding expensive?

Yes, laser cladding costs more upfront than traditional coatings, but it lowers maintenance, reduces replacements, and saves money by minimizing downtime.

- How can I get custom Stellite 6 laser cladding?

FormAlloy offers custom Stellite 6 laser cladding solutions to enhance the lifetime of parts.