In the fast-paced world of aerospace, repairing worn-out engine parts quickly and precisely is critical. That is where General Dynamics laser metal deposition techniques come in. This innovative approach allows engineers to rebuild damaged or worn metal components with incredible accuracy, often restoring them to better-than-new condition while saving time and cost.

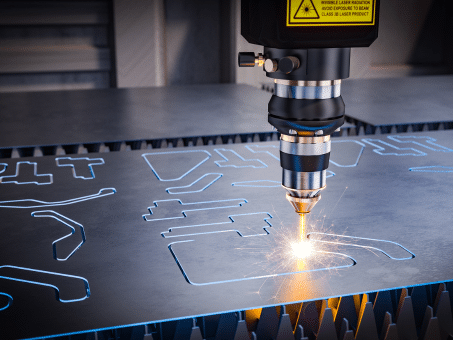

The process works a lot like applying layers of metal with a super-precise tool. Instead of traditional welding, a laser melts metal powder and fuses it onto the existing part. This method, known as laser deposition welding and more broadly as laser metal deposition, is transforming aircraft maintenance.

For example, GE Aviation has successfully restored jet engine blades using these laser-based techniques, showing how reliable and practical they are for real-world aerospace applications.

Understanding General Dynamics Laser Metal Deposition Techniques

When we talk about General Dynamics laser metal deposition techniques, we are really talking about a special way of building and fixing metal parts using lasers. Instead of carving something out of a big block of metal, engineers add metal layer by layer in exactly the right spots.

This is similar to how artists build a sculpture by stacking clay, but in this case, the “clay” is tiny metal powder particles melted by a laser. This process is part of additive manufacturing, where parts are made by adding material instead of removing it. It allows manufacturers to create shapes that were very hard or impossible to make with traditional machines, especially for aerospace parts, where strength and precision are critical.

Imagine repairing a fighter jet turbine blade that has worn down after thousands of flights. In the past, engineers would have to throw that blade away and make a new one. That process could take weeks and cost a lot of money. Today, with laser-based additive methods, engineers use a laser to melt new metal powder onto just the worn areas.

It is like filling dents on a bike frame with new metal, except the laser melts only the metal where it is needed and fuses it perfectly with the old material. The repaired blade can be just as strong, or stronger, than before.

At the core of these techniques is a controlled melt pool. A laser creates a tiny pool of molten metal on the part. Then, metal powder or wire is added to the pool and becomes part of the solid when it cools.

Each new layer bonds tightly with the one below it, building up a complete part or repairing worn material. This method allows for precise, repeatable, and cost-effective manufacturing. It reduces waste and speeds up production, which is important in aerospace, where materials like titanium are expensive, and every gram matters.

How Laser Deposition Welding Works

Laser deposition welding is a technique that allows engineers to repair or build metal parts by adding material precisely where it is needed. You can think of it like painting layers of metal onto a surface, but instead of paint, the “brush” is a powerful laser and the “paint” is metal powder or wire.

Each layer melts and bonds to the surface below it, gradually restoring or building the part back to its exact shape. This makes it extremely accurate and reliable, which is why aerospace engineers are using it for high-value components.

Each layer melts and bonds to the surface below it, gradually restoring or building the part back to its exact shape. This makes it extremely accurate and reliable, which is why aerospace engineers are using it for high-value components.

The precision of laser deposition welding also allows it to work with complex materials like titanium alloys, which are common in aircraft engines and are difficult to repair with traditional welding.

Common Challenges and How to Overcome Them

While laser metal deposition is a powerful tool for aerospace manufacturing, it comes with its own set of challenges. Engineers face issues like controlling heat, achieving a smooth surface finish, and optimizing the process to make each repair or build consistent.

Heat Control

When a laser melts metal powder onto a part, it creates a tiny pool of molten metal. If the heat is too high, it can warp the surrounding material or weaken the part. If it is too low, the metal may not bond properly.

Engineers solve this problem by carefully monitoring the laser’s power and speed in real time using advanced sensors. This is like cooking a delicate soufflé: too hot or too fast, and it collapses. With precise heat control, even high-value metals like titanium can be safely repaired or built.

Surface Finish

Another challenge is creating a smooth surface that meets strict aerospace standards. Raw layers of deposited metal can be rough, and imperfections may affect performance. Engineers use advanced software to plan the laser path and layer thickness precisely. After deposition, finishing techniques like light milling or polishing are applied to meet exact specifications. This is similar to sanding a wooden sculpture after it has been carved, making it ready for display.

Process Optimization

Each part is different, and even small variations in geometry or material can change how the laser behaves. Engineers rely on process simulation software and real-time monitoring to optimize deposition parameters for each component. This ensures that every repair or build is precise, repeatable, and cost-effective.

By combining careful heat management, precise surface finishing, and advanced process optimization, engineers overcome the challenges of laser metal deposition. These solutions make the technology reliable for high-stakes aerospace applications where safety, performance, and efficiency are critical.

Unlock New Possibilities With FormAlloy,

The aerospace industry is evolving faster than ever, and laser metal deposition techniques are at the heart of this transformation. From repairing worn jet engine blades to building complex titanium components, these laser-based methods are making aircraft maintenance faster, more precise, and more cost-effective.

FormAlloy’s solutions offer the precision, reliability, and adaptability needed to take full advantage of these techniques. Contact FormAlloy today to learn how their laser metal deposition technology can transform your aerospace projects.

Frequently Asked Questions

Q1: What are General Dynamics laser metal deposition techniques?

General Dynamics laser metal deposition techniques are advanced methods that use lasers to add metal layer by layer. They are used to repair or manufacture aerospace parts with precision, reducing costs and waste.

Q2: How does laser deposition welding work?

Laser deposition welding melts metal powder or wire with a laser, bonding it to an existing part. Each layer is added carefully, allowing engineers to repair worn components like turbine blades.

Q3: What is the difference between laser metal deposition and traditional welding?

Unlike traditional welding, laser metal deposition adds material layer by layer with precise control, reducing heat damage, improving surface finish, and enabling repairs on complex aerospace parts.

Q4: Why is laser metal deposition important in aerospace?

Laser metal deposition allows for fast repairs, reduced material waste, and the ability to work with high-value metals like titanium, making aircraft maintenance safer, faster, and more efficient.

Q5: Can laser deposition welding repair jet engine components?

Yes. Engineers use laser deposition welding to rebuild worn or damaged parts of jet engines, restoring them to near-new strength and extending their service life.

Q6: What metals can be used in laser metal deposition?

Common metals include titanium, nickel alloys, and stainless steel. Laser metal deposition works well with high-performance aerospace alloys that are difficult to repair with traditional methods.

Q7: Are these techniques cost-effective for aerospace companies?

Yes. By reducing material waste and repair times, General Dynamics laser metal deposition techniques save money and minimize aircraft downtime, making them highly cost-effective.

Q8: How do engineers control the quality of laser deposition?

Engineers use advanced sensors, software, and process optimization to control heat, layer thickness, and surface finish, ensuring every part meets strict aerospace standards.

Q9: What are some challenges of laser metal deposition?

Challenges include controlling heat, achieving smooth surfaces, and optimizing the process. Advanced monitoring and simulation software help engineers overcome these issues efficiently.

Q10: How can I explore laser metal deposition solutions?

Companies like FormAlloy offer advanced laser metal deposition systems. Contact them to learn how these technologies can improve repair and manufacturing in aerospace applications.