What is DED meta printing, and how does it work?

Let’s explain it with a story: An aerospace company finds out a $300,000 titanium part has failed its final check. Ordering a new one from overseas will take six weeks. Delays cost money, upset clients, and mess up launch schedules.

Then someone says, “What about Directed Energy Deposition?”

Just 72 hours later, the part is rebuilt. There are no extra tools or waste. It’s strong and ready to go. The part passes inspection and is installed the next week.

Sounds like a miracle? It’s not. It’s DED meta printing. And it is changing how we build, fix, and upgrade metal parts—faster than most of us think.

But you might wonder:

- How is DED different from regular 3D printing?

- Can we use it for big projects?

- Can it replace old methods like casting or machining?

Let’s break it down.

1. Traditional 3D Printing Has Limits. DED Meta Printing Breaks Them.

1.1 Where Regular Metal 3D Printing Hits a Wall

For years, we’ve used Selective Laser Melting (SLM) or Fused Deposition Modeling (FDM) to print metal. But they’re not perfect:

- They’re mostly for small parts.

- You don’t get great surface quality.

- You need extra tools and steps to finish them.

These methods are great for prototypes. But when it’s time for real industrial parts, they can’t keep up.

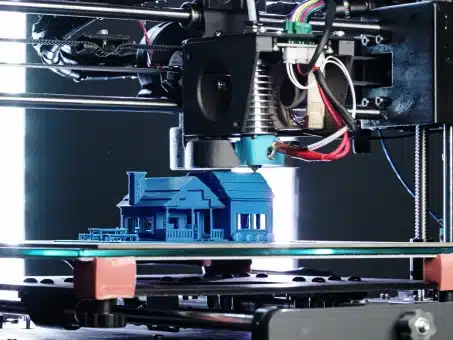

1.2 How DED Meta Printing Works

DED uses a laser or electron beam to melt metal wire or powder. It builds up the part—layer by layer—on a surface. No mold. No die. No waste.

And it:

- Works with titanium, Inconel, and other serious alloys.

- Builds large, strong parts quickly.

- Repairs or upgrades parts directly.

A study by Imran et al. (2024) proved that DED can make complex shapes with excellent strength—way beyond what old-school printing can do.

2. Aerospace Needs Precision. DED Meta Printing Delivers.

2.1 The Perfect Match

Aerospace is tough: Parts must be light, strong, and often oddly shaped. Old methods waste material and take too long.

So ask yourself:

- Can your process reduce weight without losing strength?

- Can you print hollow titanium nozzles with complex interiors?

- Can you fix a failed part without scrapping it?

2.2 Real Benefits for Aerospace

- Builds optimized, high-performance parts.

- Prints internal cooling channels in one go.

- Repairs expensive parts instead of replacing them.

Adeleke et al. (2024) demonstrated how additive manufacturing, especially DED, is revolutionizing the aerospace industry—cutting costs, speeding up development, and enabling better designs.

3. Comparing DED and SLM: Which Is Right for You?

3.1 DED vs. SLM 3D Printing Comparison

Here’s how they stack up:

| Feature | DED Meta Printing | SLM (Selective Laser Melting) |

| Material Input | Wire or powder | Powder only |

| Build Size | Large-scale parts | Small, detailed parts |

| Speed | Fast deposition rates | Slower, finer layering |

| Surface Finish | Decent with light finishing | Rough, needs heavy post-work |

| Applications | Repair, large structures | Intricate, small components |

Source: Dong-Gyu Ahn (2021)

SLM is ideal for small, intricate parts. DED is faster, cheaper, and better for full-scale manufacturing and repair.

4. Fix What You Have. Build What You Don’t.

4.1 DED = Repair Revolution

What if you find a crack in a turbine blade or a damaged oil rig part? Replacing it costs thousands and takes weeks. DED can rebuild it in hours.

For example, Kim et al. (2024) found that DED could repair forging dies used in automotive manufacturing. The repaired dies? Even stronger than the originals.

Think about that:

- Fix broken parts with less downtime.

- Rebuild worn edges—stronger than before.

- Save rare metals by restoring, not replacing.

From jet engines to nuclear valves—DED is changing the game.

5. How DED Powers the Future—Across Industries

5.1 Medical Marvels

Do you need a titanium hip joint with pores for bone growth? DED does that. No mold needed. It’s ideal for:

- Custom bone implants.

- Surgical tools with cooling channels.

- Strong, safe medical devices.

5.2 Energy & Power

Gas turbines, wind blades, drill bits—DED makes them stronger and longer-lasting.

You can:

- Repair thermal cracks

- Reinforce wear zones

- Even change alloy properties mid-print.

5.3 Defense & Military

Logistics delays jeopardize missions. That’s why the military uses portable DED units in the field.

They can:

- Fix broken armor or vehicle parts on the spot

- Print parts close to the front lines

- Upgrade parts to survive better in battle.

6. Cost, ROI, and Scaling with DED Meta Printing

6.1 Is DED Meta Printing Cost-Effective?

DED systems aren’t cheap. But lost time, wasted parts, and missed deadlines cost much more.

Think:

- How much does a week of downtime cost?

- What do you pay for scrapped metal parts?

- Could you print and repair it in-house instead?

Just ask NASA. NASA and Relativity Space used DED to 3D print rocket parts. They reduced lead time by 90%. Replaced 200 welds with one print. Launched an 85% 3D-printed rocket—and landed $1.2B in contracts.

Now that’s ROI.

6.2 Scalable. Adaptable. Ready.

DED is flexible:

- Use it in standalone factory cells.

- Add it to CNC machines for hybrid workflows.

- Mount it on robots for extra-large builds.

Wire feedstock is cheaper and safer than powder. And easier to source.

7. Is DED Meta Printing Right for Your Business?

DED meta printing doesn’t try to fit everyone. It adapts. And that’s the superpower.

Got giant parts to make? No problem. Need to fix metal gear in the field? Done. Building custom implants? Easy.

Now ask yourself:

- Are your parts too big or too tricky to make?

- Are repair costs chewing up your profits?

- Want less waste and faster results?

If you said yes, DED meta printing isn’t just a good idea. It could be your lifeline.

Still unsure? Let’s throw in some science.

In a 2024 study, Kokare and team tested WAAM (a type of DED). They compared it to CNC milling and LPBF (laser powder).

Here’s what they found:

- WAAM was the cheapest when printing 3+ parts.

- It used metal better than CNC.

- It needed less energy than LPBF.

- And it worked best for big builds.

Yes, WAAM parts require a bit of polishing after printing—some require finish machining, while others undergo heat treatment—but once completed? They’re just as strong as forged parts.

Oh, and they also reduce emissions.

So what does all that mean for you? Simple: You save money, use less metal, burn less power—and get the parts you need faster.

That’s not just smart. That’s the future of making stuff. And it’s already here.

Final Thoughts: Why Wait?

DED meta printing isn’t just another way to print metal. It’s a whole new mindset.

Less waste. More speed. Stronger parts. And smarter builds.

You’ve seen it in action:

✔ Fixing $300K aerospace parts in days.

✔ Printing complex metals like it’s no big deal.

✔ Scaling production when old-school 3D printing taps out.

So, ask yourself:

- Why waste 80% of your metal on subtractive methods?

- Why toss broken parts that DED could rebuild overnight?

- Why let your designs shrink to fit someone else’s machine limits?

You don’t have to. DED meta printing is here. It’s working. It’s winning.

At FormAlloy, we don’t just make printers. We build custom DED systems from the ground up.

No retrofits. No gimmicks. Just pure performance, precision, and power.

Need multi-material printing? Closed-loop control? Production at scale?

We’ve got you covered. With FormAlloy, you can build faster, repair smarter, and grow without limits.

Ready to level up your metal game? Let’s talk.

The real question isn’t if you’ll switch to DED meta printing, but when.

And with FormAlloy, the future isn’t just printed — it’s directed.