The first time I saw a metal part pop out of a 3D printer, I stared at it like it was alien tech. Big. Heavy. Real. It looked like something made in a massive factory, under tons of pressure, with fire, smoke, and hammers. But nope. It came out of a machine. In a shop. Quietly.

And I couldn’t stop asking questions: How is this even possible? Who checks it? How do you know it’s safe? Can it break? Will it break? And when?

Let’s say you’re printing a bracket for a truck. Or a rocket part. Or something that holds up a bridge.

Are you really going to say, “Looks good to me,” and hope for the best? No way.

In traditional factories, people melt metal and pour it into molds. They’ve been doing it for centuries. And even then, stuff goes wrong.

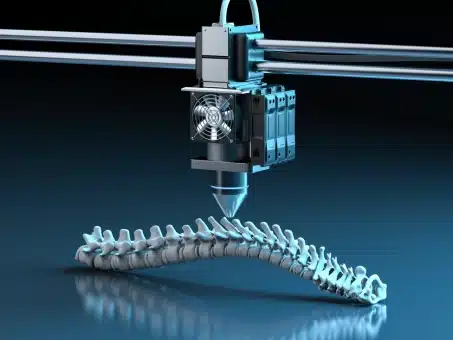

So what about a machine printing metal layer by layer, in thin strips, with a laser? That’s not just new. It’s kind of scary, which brings us to the question:

- How do you trust a metal part that didn’t come out of a mold?

- How do you prove it’s solid?

- How do you know it won’t fail when it matters most?

FormAlloy says: data. All of it. Every second, every spot, every spark. And they’ve got the numbers to back it up.

Let’s break this down.

The Machine Has Eyes

FormAlloy’s 3D printers don’t wing it. They watch everything like hawks.

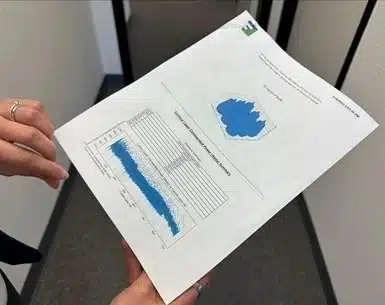

Laser power. Meltpool size. Glass lens heat. All of it? Tracked. Stored. Shown in a report.

“Within one of FormAlloy’s powder- or wire-fed DED printers, sensors are monitoring the meltpool size, the laser power, even the temperature of the optical glass,” writes Stephanie Hendrixson, Editor-in-Chief of Advanced Manufacturing.

And it’s not fluff. It’s facts.

“There’s No One Sensor…”

“There’s no one sensor that is going to be the key to unlocking the whole process,” says Melanie Lang.

So what’s the move? Use lots of them.

FormAlloy’s machines are jammed with sensors. They don’t blink. The data feeds into their brain: DEDSmart.

Source: Hendrixson

Charts. Graphs. Alerts. PDFs. You get the full picture. Not a mystery movie.

It Used to Take a PhD

Back in 2018, you had to babysit the machine. It was tricky. Needed experts. No chill.

“The DED machine in use practically required a PhD to operate,” writes Hendrixson.

But not anymore. “We’re past that now,” Lang says.

Now, the machine watches itself. And the smart part? It learned from humans.

FormAlloy asked:

- What were you looking at?

- What made you jump in?

- What caused the problem?

Boom. Those moments became data points.

“Failure Only Gets More Expensive…”

Lang drops a truth bomb: “Failure only gets more expensive the farther along you find the defect.”

If a print takes days, one small mistake = big waste. But if the machine finds the glitch early?

You don’t lose the whole thing. You don’t waste time inspecting the entire part, either.

“You’re always going to have anomalies,” Lang says, “but if you know where those anomalies are, you can avoid situations where parts fail. It’s a more targeted way of doing inspection.”

The Lens Is Talking

Even the optical glass sends signals. If it gets dirty, it heats up. And that’s bad news.

Why? The laser gets weaker. The meltpool shifts. The part could suffer.

So, DEDSmart steps in. It warns the operator before anything crashes.

As Lang said, “One of the metrics tracked in DEDSmart, for example, is the temperature of the optical glass… FormAlloy can ensure consistent laser power at the meltpool and prompt the operator to clean the glass before it creates a larger problem.”

Crisis dodged. Part saved.

“We Know Exactly How That Additive Part was Formed.”

Lang lays it out: “You can’t see what’s happening inside the mold of a casting… But with DED, we can see every layer. We can track what’s happening at every point. We know exactly how that additive part was formed.”

That’s the mic drop.

FormAlloy doesn’t guess what happened. It knows. With proof. With numbers. With time-stamped data.

You want to question the part? Go ahead. It’s all there.

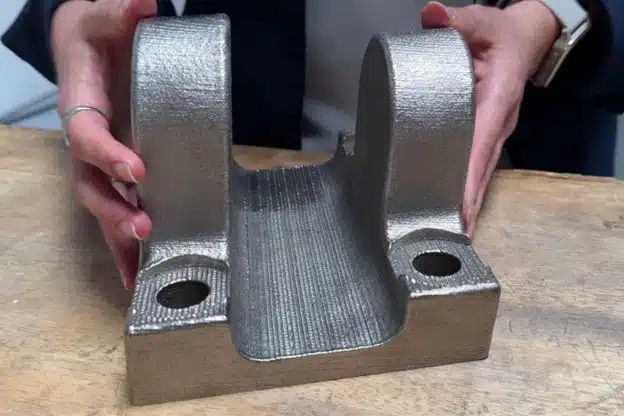

The Bracket That Could Tow a Truck

FormAlloy printed a wrecker bracket for the U.S. Marine Corps. From Inconel. In days. Not months.

Source: Hendrixson

The job? Pull a multi-ton vehicle. The goal? Speed over pretty looks. The result? Solid.

“The print was optimized for speed rather than surface finish,” Hendrixson writes.

Did it pass? Yup. Because they had the data. No mold. No guessing.

Why Wire? Here’s Why.

FormAlloy started with powder. Now, they print with wire, too.

Why switch?

- Wire is cheap.

- Easy to move.

- Already qualified for welding.

Even better? You can mix powder and wire. New metals. New tricks.

Formalloy didn’t stop at one way to print. They gave customers options.

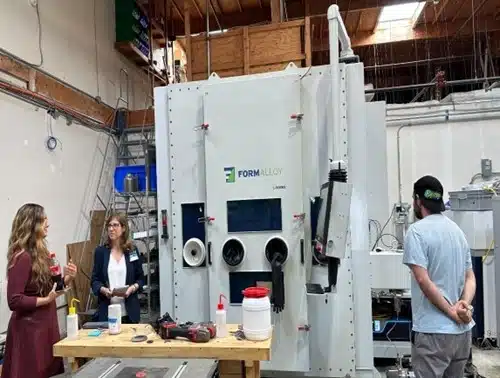

Built in San Diego. Used Everywhere.

FormAlloy builds every machine at HQ. They test them there, too.

Source: Hendrixson

Who uses them?

- The military.

- Railroads.

- Power plants.

- Labs.

They’re replacing castings. They’re skipping long lead times. They’re done waiting.

And FormAlloy? It’s growing fast.

“It Should Be Easier to Qualify an Additive Part Than a Casting.”

Lang’s not messing around. “It should be easier to qualify an additive part than a casting,” she says.

Why isn’t it?

Because people still trust the old way. Even if it hides problems.

FormAlloy’s way shows everything. But changing minds? That’s harder than building the tech.

“We’re at the point now where it’s more of a people problem — a familiarity problem — than a technology problem.”

Time to Pick a Side

Do you want parts with secrets? Or parts with receipts?

FormAlloy tracks every melt, every zap, and every move. And the proof is in your hands.

The old way is blind. This way? You see it all.

So ask yourself: Would you trust a part you can’t see inside?

👉 Ditch the doubt. Ditch the castings. Check out FormAlloy and demand the data.

DED is ready. Are you?