Metal glitters beneath harsh shop lights. Sparks crackle as Maya peers down at two turbine nozzles. One nozzle comes from EBM (Electron Beam Melting). The other springs from DED (Directed Energy Deposition). She grips both, pulses racing, and wonders: What is the difference between EBM and DED?

Her project deadline beats like a drum in her brain. She needs speed, but not at the cost of strength. She wants micro-level perfection, but the part must be big enough. Should she risk vacuum purity or shoot for volume? Should she trade tolerance for the timeline?

If she chooses EBM, will she get fatigue resistance? If she leans into DED, will she save critical hours? Which route offers on-platform repair if cracks show? Which path cuts waste and cost?

Time blurs as she switches nozzles in her hands. She tastes urgency. She pictures test rigs. She imagines certification. Which method will secure flight readiness—and her peace of mind?

So, here Maya stands—on the brink of a decision. What is the difference between EBM and DED? Will she pick surgical detail or industrial power? Will she chase microstructure or embrace speed? Which choice earns her sleep—tonight and beyond?

What Is the Difference Between EBM and DED? Core Distinctions

The difference boils down to feedstock, environment, and use case:

- EBM melts metal powder using an electron beam inside a vacuum chamber—ideal for purity and detail.

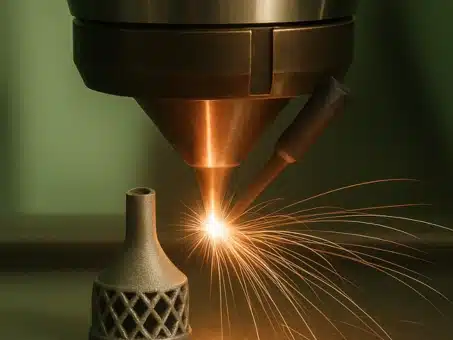

- DED deposits wire or powder while melting with a laser or beam in inert gas or air—built for volume and repairs.

Key Contrasts:

- Feedstock: EBM takes a pre-alloyed powder. DED adapts to wire or powder on demand.

- Environment: EBM’s vacuum ensures purity. DED operates in open-air or argon.

- Applications: EBM suits intricate, small parts; DED builds big geometry and fixes parts on the fly.

Takeaway: They live in different lanes—while EBM handles fine specs, DED tackles workhorse jobs.

EBM vs. DED Advanced Manufacturing Pros and Cons

A 2024 review by Ali Hakami et al. highlights EBM’s microstructure precision and fatigue resistance in critical applications like aerospace and medical implants. Meanwhile, DED dominates when it comes to large-volume builds and on-part repairs.

👍 EBM Pros

- Ultra-tight tolerances

- Excellent part density

- Vacuum-level material purity

👎 EBM Cons

- Slower build speed

- Higher machine cost

- Limited build dimensions

👍 DED Pros

- Fast and scalable

- On-part repair capabilities

- Multi-material flexibility

👎 DED Cons

- Rougher surface finish

- Requires post-machining

- Broader tolerance range

Takeaway: EBM trades time and cost for precision and material purity, while DED trades polish for power and scale.

Difference Between EBM and DED in 3D Printing

In the world of metal 3D printing, Electron Beam Melting (EBM) and Directed Energy Deposition (DED) tackle very different challenges.

EBM lays down powder in vacuum chambers, working with layer thicknesses around 30–100 µm. That makes it great for parts needing tight tolerances and fine microstructures—especially in the aerospace and medical fields.

DED, by contrast, isn’t afraid to go big. It typically prints in layer thicknesses ranging from 100 to 200 µm, making it ideal for large parts and repairs where speed and material flexibility matter more than perfect surface finish.

🔬 Academic Insight:

According to a 2025 study by Paul Gradl, Angelo Cervone, and Piero Colonna, Laser Powder Directed Energy Deposition (LP-DED) has pushed its limits. Their research showed LP-DED successfully fabricating 2.5 mm thin-walled microchannels using high-performance alloys like NASA HR-1 and GRCop-42. That’s a serious leap for DED, which traditionally lagged in fine-feature builds.

Gradl et al. (2025) also found that surface texture—caused by powder adherence, material droop, and wall angles—plays a big role in performance, especially in heat exchangers. With post-processing, DED’s textures can be tuned to improve flow, cooling, or fatigue resistance.

💡 Takeaway: While EBM still leads in thin-feature resolution and surface quality, DED is no longer stuck in the “bulk-only” zone. With research like this, DED is inching closer to EBM’s precision—especially when paired with smart post-processing.

EBM vs DED Speed Accuracy Comparison

EBM uses precise scanning—slow and meticulous. DED’s laser stream melts in a continuous flow—fast but broader.

- Build time: EBM jobs take hours. DED jobs may finish in minutes.

- Accuracy: EBM lands near ±30 µm. DED hovers around ±100–200 µm (refer to the last section for references).

Takeaway: Need runtime efficiency? DED wins. Need precision accuracy? EBM reigns.

When to Choose EBM Over DED

Opt for EBM only when microstructure matters most—turbine blades, implants, and fatigue-critical components.

Real-world examples:

- Hip implants demand ultra-low porosity and consistent strength.

- Jet engine parts rely on tight tolerances and reliable fatigue performance.

Takeaway: EBM suits high-spec, small-scale projects where time is secondary to quality.

EBM DED Material Compatibility Differences

EBM handles titanium alloys, Inconel, and cobalt-chrome powder—spotless under vacuum.

DED handles wire/powder from steel, ni alloys, and titanium—and mixes them for multi-material parts.

Oxygen risk?

- EBM’s vacuum wipes it clean.

- DED relies on argon shielding, with slight oxidation risk.

Takeaway: Choose EBM for purity; choose DED for versatility.

EBM vs. DED Surface Finish vs. Build Rate

EBM’s ~30 µm layers deliver fine surfaces. DED builds in ~100–200 µm layers—surface roughness results.

Post-Processing Needs:

- EBM: often part-ready.

- DED: frequently needs CNC finishing.

Takeaway: Pick EBM for finish, DED for fast and big.

EBM Versus DED Applications in Aerospace & Medical

Both techs have space in the industry.

- EBM builds lightweight, fatigue-resilient parts.

- DED handles tool repairs and large structures.

Aerospace Uses:

- EBM nozzles, brackets, and implants.

- DED repair of blades, dies, and add-ons.

Medical Uses:

- EBM: custom implants.

- DED: prototypes, surgical tools, bone plates.

Takeaway: Combine both for a full-scale production toolkit. Yet FormAlloy hones in on DED’s range.

EBM vs. DED Cost Comparison 2025

A 2024 cost model shows DED wins on scale—low setup, high output. EBM justifies the cost of small, high-spec parts.

Cost Highlights:

- DED saves on volume, setups, and time.

- EBM involves more expensive systems.

ROI Scenarios:

- Small, critical parts? Choose EBM.

- Large, fast builds? Choose DED.

Takeaway: DED delivers value for scale. EBM’s value shines in precision applications.

Final Thoughts: Choose Smart, Choose DED

We’ve found the difference between EBM and DED across feedstock, environment, speed, accuracy, cost, and applications.

- EBM delivers surgical-level precision in vacuum-built high-spec parts.

- DED delivers massive, rapid, repairable builds—exotic material combos included.

Which fits your project needs?

- High-detail and lab-grade purity? Go EBM.

- Large, quick, hybrid builds? Go DED—and go FormAlloy.

FormAlloy champions DED. We offer full-service expertise—wire feedstock, parameter calibration, multi-material integration, and CNC surface finishing. There is no guesswork, just results.

Are you curious about which DED solutions suit your project? Do you need help picking materials, optimizing builds, or launching repairs?

Contact FormAlloy today for a free material & cost audit. Build bold, build big—with precision, process, and power.