Speed is more than just convenience in the world of advanced manufacturing. It serves as a competitive advantage.

Imagine a jet engine blade cracking during a test flight. Replacing it could take months, but repairs could take as little as a few days. That’s the great thing about using high-speed DED metal 3D printing. It could reduce turnaround time, which makes it a total game-changer.

Traditional machining works by carving parts out of solid blocks of metal, often wasting material and time in the process. In contrast, a DED approach allows manufacturers to repair, prototype, and rebuild components, almost as quickly as they can design them.

High-speed DED is the next big thing. It gives industries like aerospace, energy, and defense a competitive advantage.

Discover Directed Energy Deposition (DED) Metal 3D Printing

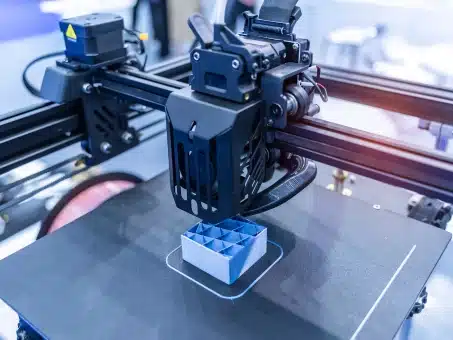

Directed Energy Deposition (DED) metal 3D printing, which brings microscopic precision, robotic control, and laser-guided speed to the metal building process. Aerospace giant Pratt & Whitney developed it to cut service time for GTF engine components by over 60%.

By using a laser to melt metal powder or wire, DED can create fully functional parts layer by layer. Imagine being able to repair or build a part from scratch.

Sounds like science fiction, doesn’t it?

Except that is exactly what DED 3D printing is all about.

LMD (Laser Metal Deposition) is a type of DED.

They both use lasers to fuse material, but LMD does so with extreme precision and detail. In comparison, DED allows you to work on larger, more complex parts with unmatched speed and scalability.

DED is extremely popular in the aerospace, automotive, and heavy tooling industries. It allows them to repair or rebuild components in days. Things have come a long way from the days when manufacturers had to discard expensive parts or wait months for custom molds.

DED technology is not just allowing manufacturers to cut back on costly repairs or replacements. It is allowing entire industries to keep moving forward by reducing downtime.

High-Speed Innovations: From LMD to EHLA

The leap from Laser Metal Deposition (LMD) to Extreme High-Speed Material Deposition (EHLA) is a dramatic one.

LMD has already proven its value in reducing downtime and building parts with amazing accuracy and precision.

But EHLA is the Formula 1 version.

Both will get you where you need to go.

EHLA tests the limits of speed combined with a level of precision and surface quality that makes building components 10 times faster than LMD. EHLA provides near-full-density deposits that are crack-free, highly durable, and metallurgically bonded to the substrate.

Like spray painting with liquid metal that hardens instantly into a flawless coat, you get to build at an industrial scale, without having to smooth out any rough edges.

DED vs Powder Bed Fusion: Which is Faster?

Imagine two workshops were fixing the same problem, and one was using Powder Bed Fusion (PBF), and the other was using Directed Energy Deposition (DED).

The PBF shop would use a lot of powder and take days to build parts with precision. The DED shop would exhibit precision, build faster, and with less waste.

DED isn’t just faster, it’s smarter.

Industries like aerospace, energy, and automotive can use DED’s ability to weld larger components, perform rapid repairs, and achieve material efficiency. However, when printing small, intricate medical implants, PBF might be the better option.

High-Throughput Metal DED Printing for Industry

Have you ever used a 3D printer to make your favorite action figures? Throughput Metal DED Printing is quite similar, except that it produces big parts, really fast.

High-throughput DED metal printing pushes more material through the system at higher speeds while maintaining precision. It allows manufacturers to produce critical components at an industrial scale.

This new technology reduces the need to ground a jet for months while waiting for a replacement blade from overseas. DED printing can take a few days, and cuts repair costs by up to 40%.

Multi-Axis DED Metal 3D Printing Systems

Traditional 3D printing comes with its own set of challenges. Most systems are built layer by layer in a fixed, vertical direction. Complex shapes would require an extra support structure that must be removed, which adds more time and cost.

Think of it like flipping a chair to paint the underside.

By using multi-axis DED metal 3D printing systems, you can make a difference, whether it is tilting, rotating, or simply maneuvering the part like a robotic arm for maximum efficiency.

Here’s what the result looks like:

- Printing complex geometries without the need for bulky supports.

- Improved surface finish as the laser can ensure that the layers blend smoothly.

- No need for post-processing support with a polished final look.

DED for Repairs: Extending the Life of Metal Components

In the past, when airlines discovered a single flaw in the turbine blade, they would have to ground the jet and order a brand-new part from overseas, but today, with the help of DED metal 3D printing, you can repair blades in-house, restoring them to near-new condition in days.

DED repairs are the next big thing. They allow airlines to control damage, rejuvenate aircraft while avoiding costly replacements, and extend the life of critical equipment.

Here are some of the industries that can benefit from DED repairs:

Aerospace:

DED can be used to repair turbine blades and blisks on-site, which dramatically reduces aircraft downtime.

Energy (Oil & Gas):

DED can be used to rebuild and improve drill heads and valves, reducing replacement costs and scrap metal.

Tools & Manufacturing:

Manufacturers use DED to extend the usable life of components instead of melting down or discarding the parts.

Why High-Speed DED Metal 3D Printing Leads the Future

In the manufacturing industry, nothing is more important than time and precision. With high-speed DED metal 3D printing, you can transform design and repair, while scaling production. The best thing about DED is that it slashes downtime on critical aerospace components, which makes sustainability a part of the manufacturing process.

Here’s what you can expect:

- Extreme high-speed processes with EHLA

- Reduce material waste significantly

- Reduce costs and extend the life of components

- Build complex geometries with high-throughput production

If you are interested in FormAlloy’s ability to unlock the full potential of high-speed DED, book a call with us today.

Frequently Asked Questions

- What is Directed Energy Deposition (DED) metal 3D printing?

DED is an additive manufacturing process that uses lasers to build or repair metal components used in aircraft and the like. - How is Laser Metal Deposition (LMD) different from other types of DED?

LMD is far more precise and allows extreme accuracy and detail, which makes it ideal for high-value aerospace and tooling applications.

- What industries benefit most from DED technology?

Aerospace, automotive, energy, and heavy manufacturing benefit the most from DED technology.

- What is Extreme High-Speed Laser Application (EHLA), and why does it matter?

EHLA is the next generation of DED, which makes it faster than LMD and suitable for industrial applications.

- How does DED compare to Powder Bed Fusion (PBF)?

PBF is better for smaller, more intricate parts; however, DED is faster and produces less waste. PBF is better for medical implants, while DED is great for building large, complex components.

- Can DED really repair turbine blades and critical aerospace parts?

Yes, DED is used to repair turbine blades and other critical aerospace parts with a significant reduction in downtime.

- Does DED reduce waste compared to traditional manufacturing?

Yes, DED allows manufacturers to repair and rebuild parts, which saves materials and reduces the scrapping of expensive metal components.

- What role does multi-axis DED printing play?

Multi-axis systems allow parts to be rotated or tilted efficiently during the printing process so that surface finish requires as little processing as possible.

- How fast is high-throughput DED compared to traditional methods?

High-throughput DED can build or repair parts in days, reducing ground time for jet engines by up to 60%.

- Why should manufacturers choose FormAlloy for DED solutions?

FormAlloy specializes in advanced DED systems, EHLA technology, and high-throughput production. They provide sustainable, scalable, and efficient metal 3D printing solutions to manufacturers.

11. What are the best laser systems for metal deposition in aviation?

The best laser systems for aviation metal deposition are high-power fiber and diode laser systems designed for precision and control. They support reliable deposition of aerospace materials like titanium and nickel alloys, deliver strong bonding, and keep heat impact low for critical aircraft components.