In 2024, the U.S. Air Force faced a familiar enemy: downtime. A mission-critical titanium component—small, complex, and custom—was grounded by a supply chain bottleneck. The replacement? A 12-week lead time from overseas. Operations stalled. Schedules slipped. Costs soared.

What caused this disruption? A single part stalled a multimillion-dollar operation. Traditional supply chains were too rigid, and conventional manufacturing couldn’t keep up with the pace. The supplier didn’t have a 3D printer that prints metal.

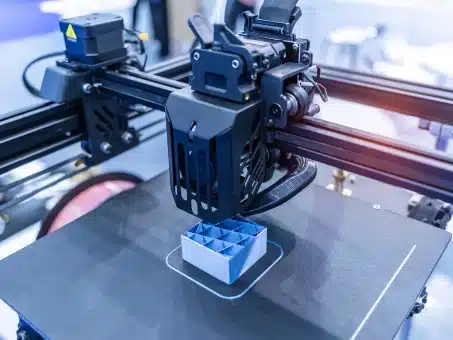

They needed a solution—one that could produce high-strength metal components on demand. They needed a large 3D printer designed for industrial-scale issues. They required a printing metal 3D printer that could adapt to their fast-moving production needs.

The impact went beyond just missed deadlines. Confidence in their supply chain eroded, relationships were strained, and engineers scrambled for alternatives. Could they bring production in-house? Could they pivot to on-demand manufacturing?

This scenario isn’t unique. Across industries, companies face supply chains that are too rigid and systems stretched thin. The real question isn’t if another disruption will hit—but whether your business is prepared to handle it.

Floor to Factory: Is Your Large 3D Printer Pulling Its Weight?

In manufacturing, size isn’t vanity—it’s value. Large 3D printers bring more than scale. They offer versatility, higher throughput, and the freedom to print complex geometries. But growth isn’t pain-free.

Scaling Up Is No Walk in the Shop

Scaling metal 3D printing strains consistency—especially in aerospace. Getachew et al. (2023) examined this industry-wide growing pain. Their study mapped the benefits but exposed the limits, too.

Complex parts? Yes. But consistency? It’s still a moving target.

Even “identical” setups showed variation—machine, software, or process shifts. Postprocessing alone introduced error margins that were hard to predict. Designs printed fine solo but failed under scaled repetition. Geometry held, but tolerances drifted. Microstructures weren’t always reliable.

The root? Small changes in temp, wear, or calibration. In aerospace, precision isn’t a preference—it’s a requirement. Almost right, it won’t fly. Literally. Defense? Not even close.

More printers don’t solve it. They spread the risk.

Getachew et al.’s work shows the challenge: scale demands structure. Without it, you’re just mass-producing uncertainty—louder, faster failure.

DEDSmart®: Because “Close Enough” Isn’t

FormAlloy’s DEDSmart® keeps metal printing tight and true. It watches the melt pool—every layer, every second. Sensors track in situ, and parameters adjust in real-time.

There is no guessing or drift. There is just locked-in precision for every build. Parts stay consistent, from batch to batch to site to site. Big jobs or small runs, the quality holds firm. Manufacturers scale up without scaling up the risk.

With DEDSmart®, the first print and last print match. That’s not luck. That’s smart control—baked into the system.

Prototype to Production: Is Your Printing Metal 3D Printer Holding You Back?

The evolution of the printing metal 3D printer is redefining what’s possible. Once tools for prototyping, they now anchor production floors. But are today’s systems holding growth hostage?

Equipment Costs Still Weigh Heavy

A 2023 study by Sæterbø and Solvang put numbers to pain. They built a cost model for atomic diffusion additive manufacturing (ADAM), a low-cost metal material extrusion (MEX) process pitched as CNC’s rival.

The model included equipment, material, time, and energy. The researchers tested three real-world scenarios against CNC machining.

Verdict? Under specific conditions, MEX can compete on cost. But those conditions are narrow. And margins? Razor thin.

Key findings included:

- Machine costs dropped up to 60% vs PBF systems

- Throughput rose, but only at small-to-medium batch sizes

- The material range was limited, locking out high-performance alloys

- Labor and post-processing still ate into savings

Cheap printers aren’t free passes. They come with trade-offs. ADAM lowers the bar, but not enough for everyone. Without wider material access, flexibility stays limited. And scaling? Still expensive. It is just…slower to bleed.

Open Materials, Open Doors

FormAlloy solves both bottlenecks. Its systems accept standard powders and wires, not locked-in cartridges, which slashes material costs. Its architecture is modular, so manufacturers start small and scale without overhauls.

The result? More metal choices. Lower cost per print. And flexibility without a forklift upgrade.

From One-Offs to On-Demand: Why Stop at Prototypes?

Metal 3D printing has moved beyond “what if?” It answers real-world needs. Still, many firms treat it as a sandbox. Why limit its role?

Integration Kills the Buzz

Ian Wright’s 2024 roundup pulled no punches. He interviewed leaders from EOS, 3D Systems, Materialise, and insiders from SPEE3D, MSAM, and Boston Micro.

Together, they sketched a blunt picture of AM’s reality. Spoiler: it’s not plug-and-play. Not even close.

Wright’s method? Go straight to the source. He asked experts what worked—and what still didn’t. Their top challenge? Integrating AM into real production.

- EOS warned of overpromising, underdelivering, and engineering gaps

- 3D Systems stressed the lack of certified, transparent data

- SPEE3D pointed to compliance bottlenecks and powder issues

- Materialise flagged that many AM firms still aren’t profitable

Most metal systems remain isolated.

- There is no direct line into MES or ERP.

- Engineers waste hours converting tolerances and specs.

- Certification drags. Validation stalls. ROI never arrives.

AM works for prototypes and one-offs. But when it’s time to scale or integrate, the tech freezes, adoption halts, and even large 3D printers gather dust in silos. The industry isn’t dying, but the hype is.

Wright’s takeaway: AM won’t win alone. Without smart integration, it will remain a side act.

Plug In, Power Up

FormAlloy’s Directed Energy Deposition integrates easily. It complements CNC workflows. Machines talk to each other. Engineers stay in familiar software. Parts print with traceability and speed. And yes, the certification path is baked in. Their systems fit the floor—not the lab.

Procurement to Production: Are You Wasting Weeks?

Speed wins contracts, and flexibility retains them. Waiting 12 weeks for parts is a liability. Why outsource what you could print in-house?

Supply Chains Keep Getting Punched

Recent disruptions exposed a truth: traditional supply chains aren’t nimble. A 2024 McKinsey report by Alicke, Foster, and Trautwein details how fragile they’ve become. Based on the McKinsey Global Supply Chain Leader Survey, the findings are clear—and concerning:

- 90% of surveyed supply chain executives experienced major disruptions in 2024.

- 73% implemented dual-sourcing; 60% shifted toward regionalization.

- 60% reached tier-one visibility, but deeper-tier insight declined.

- Only 30% of boards understand supply chain risk well.

- Just 10% of firms fully deployed modern planning systems.

The researchers conducted this research via a structured survey targeting global supply chain leaders. McKinsey analyzed operational changes, risk exposure, and organizational readiness across industries. The results show a growing gap between digital ambition and execution.

Many companies took action after COVID-19—building buffers, dual-sourcing, and investing in planning tools—but momentum is stalling. Investments in digital systems have plateaued. Deeper visibility into suppliers is falling. Talent shortages persist.

One key problem? Many boards still don’t grasp supply chain fragility. Few prioritize long-term resilience. Most firms still take weeks to respond to disruptions. That’s far too slow in today’s volatile world.

Even minor parts now become critical bottlenecks. Delays cascade. Margins suffer. Contracts slip. Clients leave. According to McKinsey, resilience isn’t just a buzzword—it’s a boardroom imperative. Traditional, linear logistics no longer hold. Complexity demands agility.

Print Here, Ship Less

FormAlloy flips the model. Need titanium brackets tomorrow? Print them tonight. Their large 3D printer scales output without delay. That means fewer purchase orders, fewer customs hangups, and fewer angry clients. Additive isn’t a supplement—it’s your new default.

Want to Lead or Lag? Ask the Printer

You have the data. You have the need. Do you have the printer? Metal 3D printing isn’t a trend—it’s a tool. And FormAlloy builds the tools that scale.

Their DEDSmart® technology produces consistent, certifiable results. Their systems handle exotic metals, large builds, and harsh timelines. They fit the floor. They talk to your systems. They don’t guess—they verify.

So, what’s holding you back? Another delay? Another late part? Another missed bid?

Or are you ready to scale with a 3D printer that prints metal? Talk to FormAlloy today. The future isn’t offshore. It’s on your floor.