Machine parts can be expensive and hard to replace. They get old, crack, or break. And buying new ones costs a lot of time and money.

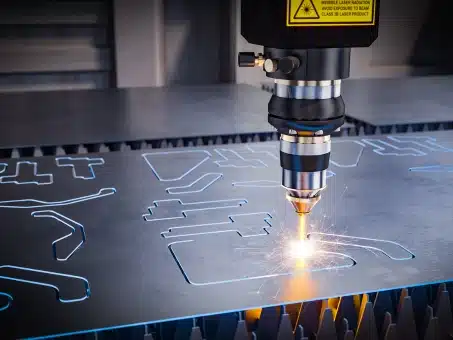

Laser metal deposition services let you fix parts by adding metal back onto them. A laser melts the metal powder and builds up new layers right where it’s needed. It works much like 3D printing—but for metal. Companies in aerospace, energy, healthcare, and more use this method because it’s fast, clean, and strong.

So, do you want to save money? Do you want to fix parts so they last longer? Do you want repairs that match the new parts in quality? Laser metal deposition services can solve these problems.

How Do Laser Metal Deposition Services Work?

Laser metal deposition services use lasers and metal powder to fix or build parts in simple steps:

- A laser heats the metal part.

- Metal powder is blown into the hot spot.

- The powder melts and sticks.

- This repeats, layer by layer.

- A new shape forms, or the old one gets stronger.

It’s like building with metal blocks—but much more precise.

🔬 2025 Research Says:

A study by Piotr Koruba et al. (2025) tested fixing airplane engine rings with this process. They found:

- The new metal didn’t crack.

- The repaired part became almost twice as hard.

- It worked on flat, round, and curved areas.

- The part was safe and ready to use again.

It shows how LMD services work. They make big, important parts as good as new.

What Do Laser Metal Deposition Services Cost?

The cost depends on three things:

- The size of the part

- The type of metal used

- And how detailed or complex the job is

💰 Typical Price Ranges (Based on Industry Data):

- Small repairs (about 200 cm³): $260–$980

- Medium parts (500–1000 cm³): $650–$4,900

- Large builds (1000+ cm³): $5,000 or more

These numbers come from a 2023 report by AMPOWER Academy, which found that LMD costs between €1.20 and €4.50 per cubic centimeter for materials and processing.

🧾 Bottom line: The bigger and more complex the part, the more it costs. But in most cases, LMD services cost less than replacing the whole part—which saves money and time.

🔬 2025 Research Says:

In 2025, a group of engineers from the University of Toronto built a tool called AIDED. It uses computers to find the best laser settings. In about an hour, it:

- Picks laser speed & heat.

- Makes parts stronger with fewer mistakes.

- Works for airplanes, cars, and medical parts.

- Saves time and money.

This study shows how laser metal deposition services are getting smarter and more efficient.

Where to Get Laser Metal Deposition Services?

Search for laser metal deposition services here:

- Metal repair shops

- Aerospace or auto manufacturers

- 3D metal printing companies

- FormAlloy (we do this, too)

You can find local shops in your city—or ship parts to experts.

Who Offers Laser Metal Deposition Services Near Me?

Do you want to know who offers laser metal deposition services near you? Try this:

- Google Maps

- Ask local welding or machining shops

- Use directories like ThomasNet or MFG.com

FormAlloy is one provider that ships globally to many industries.

When to Choose Laser Metal Deposition Services?

Use laser metal deposition services when:

- Parts are cracked or worn

- You want to save costs and time

- You need custom shapes or extra strength

- A full part replacement is expensive or slow

If these sound like your problems, then it’s the right time to choose this technology.

Laser Metal Deposition Services vs. Laser Cladding

Here’s a look at both methods:

| Feature | LMD (Laser Metal Deposition) | HSLC (High-Speed Laser Cladding) |

| Layer Depth | Deep, 3D builds | Thin, surface layer only |

| Purpose | Repairs, rebuild parts | Adds protective coatings |

| Flexibility | High | Moderate |

🔬 2025 Research Says:

A study by Ortiz et al. in The International Journal of Advanced Manufacturing Technology tested both methods in June 2025. They used the same machine and steel, with nickel and iron powders. They found:

- Nickel coatings needed heat first to prevent cracks.

- Iron powder cracked in HSLC when hot.

- HSLC was 130% faster.

- HSLC used 80% less gas.

- HSLC made strong layers—but cracks can happen.

🧠 Why It Matters:

Laser metal deposition services are best for thick, strong repairs. HSLC works for thin, fast coatings—but may crack under some conditions.

Are Laser Metal Deposition Services Safe?

Yes, they are—if done right:

✅ Safety Facts:

- Operators wear protective glasses

- Machines are closed and have ventilation

- Powders are handled with care

Industry safety guides, like ANSI Z136 and OSHA, say there are no known risks when rules are followed.

Benefits of Laser Metal Deposition Services

Still, wondering what makes laser metal deposition services great?

🌟 Top Benefits:

- Stronger parts

- Fast repair times

- Less waste material

- Eco-friendly

- Custom shapes and layers

- Saves 40–70% compared to replacing parts

🔬 2025 Study Proves It:

Christian Mills et al. (2025), from Leibniz University Hanover (Germany), published a paper in the International Journal of Advanced Manufacturing Technology. They tested this method on bearings under heavy use. They found:

- Repaired bearings lasted much longer.

- They became stronger and more reliable.

- The method worked for different shapes.

It shows laser metal deposition services fix parts so machines work longer.

FAQs About Laser Metal Deposition Services

FAQs About Laser Metal Deposition Services

- Why use laser metal deposition services?

It cuts costs, strengthens parts, and makes them last longer.

- How do laser metal deposition services work?

A laser melts powder to build up parts layer by layer.

- What do laser metal deposition services cost?

From $200 to $5,000+ based on size, metal, and detail.

- Where to get laser metal deposition services?

Metal shops, 3D printers, or FormAlloy can help.

- Who offers laser metal deposition services near me?

Check Google, local shops, or online services.

- When to choose laser metal deposition services?

When parts are worn or need custom fixes, and cost/ time matters.

- Laser metal deposition services vs laser cladding?

LMD builds thick, strong parts; cladding adds a thin layer.

- Are laser metal deposition services safe?

Yes. They follow strict rules with protective gear and sealed machines.

- What are the benefits of laser metal deposition services?

It makes fast, strong, low-waste repairs and builds.

- Can LMD be used for small parts?

Yes. It works for tiny tools or big machine parts.

The Future of Metal Repair Is Here

In today’s world, we don’t always need to throw things away. We can fix, upgrade, and rebuild with smart technology. That’s why you should use laser metal deposition services. It’s not just a way to repair parts—it’s a way to build a better, cleaner, and more cost-saving future.

FormAlloy provides this service with top machines, expert teams, and safe methods. Want parts fixed to work like new ones? Want to save money and cut waste? Want repairs to be quick, strong, and perfect? Laser metal deposition services give you those answers.

📞 Take Action Now

Ready to try laser metal deposition services? Contact FormAlloy to restore or build your metal parts—faster, better, and stronger.