You walk into a busy aerospace shop. Big metal parts are everywhere. Every part must be strong, light, and perfect. But how do we build them faster? How do we make them right every time?

Can a smart machine check every layer as it builds? Can it fix problems while printing? Can it replay perfect parts again and again?

Yes. That’s what DED additive manufacturing can do. And it’s changing the future of how we build metal aerospace parts.

How DED Advanced Manufacturing Ensures Aerospace Part Consistency

Every part for space or flight must be the same. Old methods sometimes make small mistakes. Even a tiny error can ruin the part.

FormAlloy’s DEDsmart® helps stop that. It watches the laser, feed rate, and melt pool while building. It saves every setting. You can play the same settings again and again.

In 2025, Paul R. Gradl from NASA conducted a thorough study at Delft University. He used LP DED to build tiny heat exchanger parts. These parts had very thin walls—just 1 mm.

He measured every wall, curve, and surface. He tested how heat, shape, and polish changed results. And he used NASA’s HR-1 alloy, which works well in hot and high-pressure places.

Gradl found that LP DED made strong, repeatable parts. He even polished and treated them to make the surfaces smoother. It proves that DED can make parts the same way every time.

How to Use Real-Time Monitoring in DED Advanced Manufacturing

If you only check parts after they’re built, it’s too late. You waste time and metal. You need to see what’s happening live.

DEDsmart® shows the melt pool video in real time. It also saves all the data. If anything goes wrong, you can stop or fix it right away.

The same study by Gradl also showed how this monitoring helps. He tracked surface details during each build. It helped keep everything under control.

How Closed-loop Control Improves Aerospace Part Reliability

If a machine keeps using the same settings, problems may still happen. Heat can change. Metal can act differently. That makes the part weak.

DEDsmart® fixes this by using feedback. If it sees the melt pool change, it adjusts the laser or feed. It keeps the part strong.

A 2024 study by Kannapinn et al. used a digital twin and AI. It changed settings in real time to reduce stress in parts. That proves feedback helps make better parts.

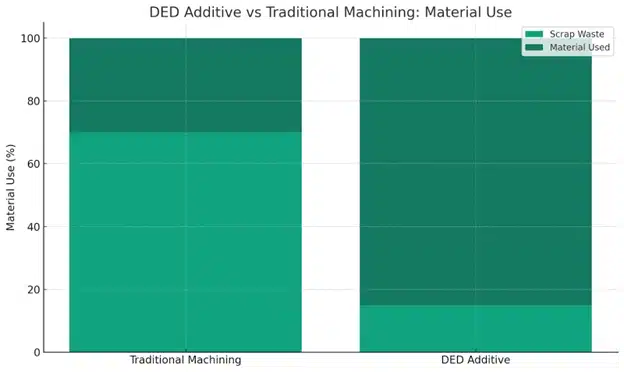

How DED Advanced Manufacturing Reduces Aerospace Material Waste

Old ways cut away lots of metal. That becomes waste. It costs more and hurts the planet.

DED builds only what’s needed. No extra. It can also fix old parts instead of throwing them out.

Rabalo et al. (2025) conducted a systematic review to show how it works. They used DED with just a little machining. And they saved a lot of material.

See the chart below:

DED vs Traditional Machining

How to Qualify Aerospace Parts Using DEDsmart® Monitoring

To use a part in space or flight, it must pass tests. You need proof that it was built right.

DEDsmart® saves all build videos, temperatures, and scans. You can check any part after it’s done. It helps get the part approved faster.

Gradl wrote about this in a two-year-old NASA review. He showed how saved data helps teams certify aerospace parts faster.

How to Achieve Repeatable Builds in DED Advanced Manufacturing

When builds use different settings, you waste time testing. It slows down the work. You want each build to work the same way.

DEDsmart® saves your best build recipe. Then, it plays it again, slice by slice. That gives you the same part every time.

Gradl’s team, in a 2022 conference paper, proved this, too. They built parts with 1 mm-thick walls again and again. The results stayed the same. That shows DED can build strong, repeatable parts.

How Optical Melt Pool Monitoring Boosts Aerospace Quality Control

If you don’t watch the melt pool, bad things can happen. Cracks, holes, or weak spots may form.

DEDsmart® watches the melt pool with a camera. It tracks size and heat. If something goes wrong, you fix it right away.

A February 2025 study by Era et al. used a thermal camera and AI. It found defects with 99% accuracy by watching the melt pool heat. That proves this tech works.

How Dynamic Layer Inspection Ensures Precision in Aerospace DED

Mistakes can build up layer by layer. That makes parts crooked. You need to measure each layer as it’s made.

DEDsmart® scans each new layer with a laser. If it finds a problem, it corrects it. That keeps the shape perfect.

How DEDsmart Transforms Aerospace Part Manufacturing

Old machines don’t give enough feedback. They are slow to certify parts. You need smart tools.

DEDsmart® puts all tools in one place. It watches, adjusts, inspects, and records every build. That makes the whole process better.

How Real-time Data Helps Optimize DED Additive Aerospace Processes

Without live data, engineers guess and test. That’s slow.

DEDsmart® gives fast updates. Engineers fix problems right away or adjust for the next build. It saves time and cuts waste.

Fly Smarter, Build Better

Now you see how DED additive manufacturing helps. It builds strong parts, the same every time, and with less waste. It gives you live data, smart fixes, and faster part approval.

NASA and top scientists back this tech. And only FormAlloy’s DEDsmart® brings all this into one smart system.

Want to build better aerospace parts? Talk to FormAlloy today.

FAQs

- What is DED additive manufacturing for aerospace parts?

It’s a way to 3D print metal aerospace parts layer by layer. - How does DEDsmart® ensure part consistency?

It saves build settings and repeats them every time. - Can real-time monitoring detect defects early?

Yes. It shows live video and heat data during printing. - Does closed-loop control improve reliability?

Yes. It adjusts settings to keep builds stable and strong. - How much waste reduction does DED offer?

A lot. It builds only what you need and fixes parts, too. - Can parts be qualified using DEDsmart® logs?

Yes. It saves all data to help get parts certified. - Is repeatability guaranteed?

Yes. Saved recipes give the same results every time. - How does melt pool monitoring improve control?

It finds problems early so you can fix them fast. - What is the benefit of layer inspection?

Each layer is checked for accuracy before moving on. - How does real-time data speed optimization?

It helps engineers tune settings faster and cut waste.