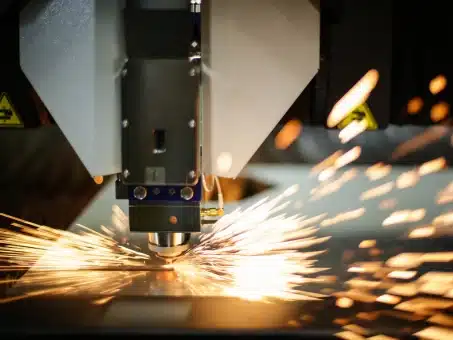

Directed Energy Deposition (DED) is the talk of the manufacturing world. It’s quick, accurate, and adaptable. Think of using a laser to melt materials and build them layer by layer. That’s what DED does. It stands out in additive manufacturing as it helps create, repair, and design parts smarter. DED shines in industries that need precision. And it’s also more effective than old methods.

In today’s fast-paced world, every business wants to save money and speed up production. Sadly, older manufacturing methods often fall short. They waste time and money and cannot handle complex tasks well.

So, how do you face these issues and stay ahead? Meet DED. It’s changing the game for manufacturers. Let’s find out how it works and why you should adopt it.

Old-School Methods Are So Last Century

Still using traditional methods like casting as your go-to solution? It might be time for a rethink. Casting has its place—but when it comes to flexibility, speed, and customization, it falls short. That’s where Directed Energy Deposition (DED) steps in.

Let’s be clear: CNC machining isn’t going anywhere. In fact, it’s often a key player in post-processing for AM parts. But relying on it as your primary method can slow things down and drive up costs—especially when speed and agility are what you need most.

As for injection molding? That’s a different story. It excels in high-volume production, but doesn’t offer the design freedom or small-batch efficiency that additive manufacturing provides.

A study by Nivasanon et al. (2024) shows how older methods can become a financial bottleneck. They found that small production runs using conventional techniques significantly raised costs. Additive manufacturing, by contrast, keeps expenses in check—without sacrificing complexity.

Intricate geometries, tight timelines, and changing requirements? Traditional methods struggle to keep up. DED was built for this moment—and it’s ready to deliver.

Directed Energy Deposition (DED) Brings Speed and Flexibility

DED is faster, smarter, and more adaptable. A study by Aversa et al. (2023) found that adjusting DED settings, like the laser size, can pump up production by 170%.

Need repairs or custom features? DED has your back. It shortens wait times and maintains incredible flexibility. Whether you want unique shapes or different materials, DED can create them all. Speed and flexibility—what a perfect combo!

Complex Parts Are A Nightmare—Until Now

Creating intricate designs? Traditional methods often fail here. Getting precise angles and fine details is tricky. According to a 2021 study by Cao et al., laser powder bed fusion (LPBF) tackles these challenges effectively.

The researchers noticed better quality after using machine learning to optimize LPBF settings. Their tests showed improved surface smoothness and accuracy compared to old methods.

Need precision? LPBF can deliver. Want complex parts? DED makes it happen without sacrificing quality.

Directed Energy Deposition (DED) Nails Precision Every Time

DED takes precision to the next level. Layer by layer, DED creates parts with intricate features and tight tolerances. A study by Hasan et al. (2024) showed that Directed Energy Deposition (DED) achieves high precision, with a mean absolute error of just 7.47 °C in thermal simulations, improving complex geometries.

DED suits industries like aerospace, automotive, and medical devices. Need complex designs? DED delivers without compromising quality.

Inconsistent Quality? Time to Get It Together

Many manufacturers know all too well about inconsistent quality. Parts failing to meet specs lead to quick reworks, which is a hassle and a loss. A 2004 study by Cauchick Miguel and Pontel revealed that warranty claims hurt manufacturers’ profitability.

Why does this happen? Traditional methods lack real-time checks, which means defects can go unnoticed. As production ramps up, quality suffers, leading to delays, unhappy customers, and increased costs.

Directed Energy Deposition (DED) Makes Quality Control a Breeze

What does DED offer? It builds parts layer by layer with precise material placement every time, eliminating unnoticed defects.

With DED’s real-time monitoring, quality remains consistent. Complex parts? Easy deal. Tight tolerances? No problem here. Industries like aerospace and medical devices prosper with DED as it ensures high quality and low rework.

Can’t Keep Up with Demand? Directed Energy Deposition (DED) to the Rescue

Slow production is a burden, especially with today’s fast demand. Customers want products now—and if you can’t deliver, your competitor will. Traditional methods fall behind.

Research by Ngo et al. (2018) shows they have longer production times than modern methods like DED.

DED Speeds Things Up

DED is incredibly fast. It builds parts layer by layer without slow molds or cumbersome setups. A study by Jiang and Ma (2020) found that Directed Energy Deposition (DED) reduces production times compared to CNC machining. Need a part done ASAP? DED is your hero.

And it’s not only fast. DED is scalable. Whether making one part or a hundred, it keeps up. There will be no more long waits, as DED speeds up production while maintaining quality.

Precision—A Must-Have

Missing the mark is simply unacceptable in manufacturing. A 2024 study by Shang et al. presented an amazing framework called AIDED, which uses machine learning to improve DED performance. The results? Near-perfect precision, with impressive scores of R² = 0.995 for single-track and 0.969 for multi-track simulations. Even a small mistake can create big problems in critical fields like aerospace.

DED Is All About Precision

DED excels at precision. It places material exactly where it belongs—no guessing involved. A 2024 study by Imran et al. supports this. It shows that directed energy deposition (DED) achieves tolerances that rival or even beat traditional methods. Need tight tolerances for your parts? DED is ready to deliver. It adjusts in real-time to ensure parts stay accurate. Precision? All day long.

Repairs Don’t Have to Break the Bank

Repairing parts is no one’s favorite task, especially in aerospace or defense, where downtime can cost a fortune. Traditional repair methods? They’re slow and costly. According to the Kaizen Institute, repairs in aerospace can easily set you back hundreds of thousands of dollars per part.

DED Slashes Repair Costs

Here comes DED to save the day. DED is faster, more cost-effective, and less of a headache for repairs. Its layer-by-layer approach allows you to fix parts without tossing them. A study by Saboori et al. (2019) discovered that DED can lower repair costs by up to 50%. Why throw a part away when you can restore it right there?

There will be no more pricey downtime or expensive repairs. DED keeps everything moving, saving time and money alike.

DEDSmart®: The Only Tool You Need

FormAlloy’s DEDSmart® takes your process up a notch. It offers real-time monitoring, precision control, and smart analytics. It isn’t fluff—it’s total command of your build from start to finish.

Whether fixing an existing part or creating a new one, DEDSmart® ensures consistent quality and work. Expect no surprises or wasted time.

With features like Melt Pool Control, optical monitoring, and feedback loops, DEDSmart® ensures better builds and faster results. It’s everything you need to work smarter, not harder.

FormAlloy was named one of San Diego’s Cool Companies by Connect, a nod to our innovation and momentum in additive manufacturing. We’re proud to represent the region—and to keep pushing the future of metal 3D printing forward.

Ready to level up your manufacturing? Let’s talk DEDSmart®.