As an aerospace engineer, you know the stress and pressure of a grounded jet engine. A single damaged turbine blade can bring operations to a halt.

Replacements can cost millions while repairs take months. That’s time airlines don’t have.

With innovators like FormAlloy, a leader in robotic laser metal deposition, there is a way to manage repairs quickly and cost-effectively. While it might make sense to replace lightweight prototypes, every iteration will come with an increase in costs, and time is of the essence in aerospace.

So what do you do?

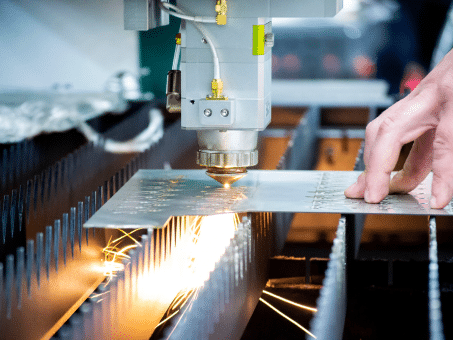

You go for robotic laser metal deposition (LMD), the perfect solution for repairing and building high-performance metal parts. LMD ensures that airlines can operate without costly delays, providing a sense of relief and optimism for the future of aerospace engineering.

LMD combines robotics, lasers, and additive manufacturing to redefine aerospace engineering with a level of precision, sustainability, and reliability that is nothing short of inspiring.

So if you are looking to keep planes in the sky without exorbitant costs and excess waste, using LMD repairs is the way to go.

Why Use Laser Metal Deposition Technology for Manufacturing?

While traditional manufacturing methods like CNC machining have carried the industry for decades, they can be wasteful.

Recent studies show that CNC machining can result in 15-30% of metal becoming scrap due to machining errors. Even expensive materials like titanium end up as scrap metal.

Traditional systems are prone to design limitations and inefficiencies, which can result in more problems for the airlines. When creating parts like turbine blades or structural components, factories often face the choice of discarding expensive parts or enduring long, costly production cycles.

Robotic laser metal deposition is a breakthrough for aerospace manufacturers. Allowing them to reduce waste and energy consumption by up to 25%. By using LMD, manufacturers can repair costly parts more efficiently, while supporting the creation of complex geometries, making the process as efficient as possible.

LMD is far more advanced and less expensive than CNC machining. It not only cuts larger blocks of metal with minimal waste, but it does so with higher accuracy, so that manufacturers can repair costly parts more efficiently.

LMD provides far greater sustainability, which makes it a responsible and forward-thinking choice for the aerospace, automotive, energy, and defense industries.

How Does Robotic Laser Metal Deposition Work?

Robotic LMD is a kind of 3D printer for metals, but instead of creating figurines, you get to build precision-engineered components.

Here’s how robotics laser metal deposition works:

- The LMD system delivers a stream of metal powder or wire onto the path of a high-powered laser.

- The high-powered laser instantly melts the powder, creating a molten pool which then forms a specific shape.

- The molten pool cools, and it solidifies into precise layers to form the final shape. A robotics arm guides this step with the help of a digital CAD model.

- The robotic system adjusts positions and speed to ensure precise layer deposition and optimal structural integrity. The robotic LMD helps to create complex curves and geometric shapes, with even coating and accuracy.

What Industries Use Robotic Laser Metal Deposition?

Robotic laser metal deposition (LMD) is transforming multiple industries, making precision-engineered metal components more accessible.

Aerospace manufacturers rely on LMD technology to produce complex geometries efficiently and restore parts quickly and safely. The reduced downtime for airlines and OEMs saves millions of dollars, making LMD ideal for airlines.

The use of LMD technology is quickly gaining popularity in the automotive, energy, and defense industries. The LMD market reached $300 million in 2024 and will grow to $755 million in 2025.

LMD technology provides faster turnaround times and significant material savings, which makes it one of the most important innovations of the century and a catalyst for new design paradigms that focus on lighter, stronger, and more customized parts.

To put it simply, LMD is enabling manufacturers to do what was once thought impossible in the aerospace, energy, and medical industries.

How Does Robotic LMD Improve Sustainability in Manufacturing?

Sustainability is more than a buzzword that manufacturers use to pad out their marketing materials. It is the need of the hour as regulatory pressure arises and consumer expectations change.

Sustainable manufacturing initiatives can reduce industrial resource consumption by 50% which makes technologies such as LMD not only a strategic option but a much more efficient alternative.

Unlike traditional subtractive methods, Robotic LMD reduces wasted material by over 80%, making it one of the most effective ways to work with high-cost alloys such as titanium and Inconel.

As the global manufacturing landscape moves towards a more sustainable approach, it is necessary to use advanced manufacturing techniques such as LMD that can cut emissions by up to 25%.

Why is Robotic LMD Important for Future Aerospace Innovation?

The aerospace industry is a demanding space, and so saving expensive materials is invaluable. Robotic LMD is gaining popularity for its ability to reduce costs and downtime. This technology is not just a trend; it’s a crucial innovation that is shaping the future of aerospace engineering.

Lightweight, High-Performing Components

Weight matters a lot in aerospace, and reducing as little as 1kg on a commercial aircraft can save thousands of dollars. That is made possible by LMD’s precise deposition of metals such as titanium, nickel, and other high-performance alloys.

These metals are known for their strength-to-weight ratio, making them ideal for minimizing scrap and being instrumental in the machining process.

Repairs Over Replacement

Back in the 1970s and 80s, damaged turbine blades would get replaced. These methods were not just labor-intensive; they were not as effective, and led to longer aircraft downtime, which resulted in higher costs.

Repairs only became feasible after the 1990s, when the Sandia National Laboratories proposed the use of Laser Direct Metal Deposition (LDMD), which led to what we now call LMD today.

By the 2010s, more and more industries were adopting LMD, and soon it was a common practice for aerospace and energy sectors to use LMD to repair and rebuild components layer by layer, instead of wasting high-value parts.

Today, LMD can not only extend the service life of aircraft components, but it can also reduce waste by 80%.

Who is the Robotic Laser Metal Deposition Leader?

FormAlloy stands as the global leader for Robotic Laser Metal Deposition, having pioneered the advanced additive manufacturing system, component, and service. Its proprietary LMD systems are among the most trusted in the aerospace sector.

FormAlloy offers unmatched precision, reliability, and scalability, making its cutting-edge hardware not only customizable but strategically designed for mission-critical applications.

FormAlloy is redefining the manufacturing process using Robotic LMD.

Want to see FormAlloy’s systems in action? Book a consultation with us today.

Frequently Asked Questions

1. What is robotic laser metal deposition?

LMD is an additive manufacturing process that uses lasers and robotics to deposit metal, layer by layer, to build and repair parts.

2. Why is LMD better than traditional machining?

LMD reduces material waste and enables aircraft manufacturers to repair high-value performance metal parts rather than replace them.

3. How does Robotic LMD improve the manufacturing process?

Robotic LMD improves the manufacturing process by adding precision and adaptability, making it easier to produce and repair complex parts.

4. What are some of the industries that use Robotic LMD?

Aerospace, automotive, energy, and defense are among the industries that use LMD technology.

5. Can Robotic LMD be used for repairs?

Yes, manufacturers use Robotic LMD to repair turbine blades, molds, and high-value components.

6. Is LMD sustainable?

Yes, LMD can significantly reduce material wastage and is more sustainable than traditional machining.

7. What materials can be used in LMD?

LMD can be used to manufacture parts using metals such as titanium, steel, and nickel alloys.

8. How fast is Robotic LMD compared to traditional methods?

Robotic LMD is faster at building complex parts and can reduce production times by up to 40%.

9. What makes a company a leader in LMD?

FormAlloy is one of the leading providers of LMD technology, known for its innovative approach and success across multiple industries.

10. Why choose FormAlloy for LMD solutions?

FormAlloy combines cutting-edge technology, precision lasers, and industry expertise to deliver scalable results.