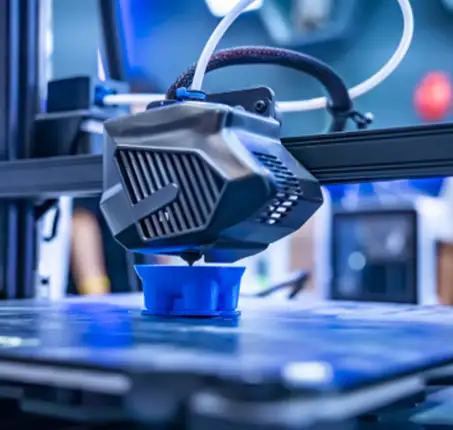

Have you ever wondered how long it takes for airplanes to get a brand-new part? Something stronger, lighter, and more efficient? Perhaps a few weeks, or a month? Well, thanks to aerospace metal 3D printing, we can shape a heavy block of metal into the perfect part layer by layer, creating a fully functional component for airplanes in just a few days.

This is a far cry from the traditional aircraft manufacturing methods that require extensive casting, carving, and, most importantly, result in waste. Conventional techniques take longer, cost more, and are less efficient.

With aerospace metal 3D printing, these obstacles are a thing of the past. It understands the role Directed Energy Deposition (DED) plays in aerospace innovation. With Directed Energy Deposition (DED), a laser or other energy source melts metal wire or powder and “prints” it layer by layer right onto a base or the part you’re building, turning raw metal into a precise, ready-to-use component without needing a mold.

Advantages of Metal Additive Manufacturing for the Aerospace Industry

Have you ever wondered how engineers build complex airplane parts? How do they decide what shape the component takes, and what machines bring their ideas to life?

With traditional manufacturing, both design and execution were limited. But thanks to metal additive manufacturing, the possibilities are endless, which makes this technology invaluable for the aerospace industry.

Design Freedom

With metal additive manufacturing, engineers are no longer restricted to building machine parts that require extensive cutting and material waste. This process builds parts layer by layer, which makes it easier to create complex designs.

Building a part that includes a built-in cooling channel was unheard of with traditional manufacturing methods. With metal additive manufacturing, you have the flexibility to make something lighter and more aerodynamic.

Faster Prototyping & Production

Traditional methods meant prototyping took months. But metal additive manufacturing allows you to build parts in days, shorten development cycles, and help companies meet their production goals faster.

Not to mention, engineers can develop lightweight aerospace components that don’t compromise on strength.

Utilize Stronger Materials

Airplane components are under extreme conditions like heat, stress, and pressure. Metal additive manufacturing makes the process faster and more efficient. This means you can use special materials like titanium and nickel-based alloys to build parts that are not only lighter but also stronger.

These components are ideal for aerospace because they help create structural parts and flight-critical elements. This is exactly what aircraft manufacturers are looking for.

Why Aerospace Companies Choose FormAlloy

FormAlloy is known for flagship technologies like DEDSmart® Directed Energy Deposition (DED) that manufacture and repair metal parts with repeatable precision.

The aerospace industry has changed for the better because of the cutting-edge technology FormAlloy offers. With a manufacturing partner like FormAlloy by your side, you can create even the most complex patterns flawlessly.

Ready to upgrade your aerospace manufacturing? Contact FormAlloy today to discover streamlined production that accelerates your workflows.

Frequently Asked Questions

Q1: What exactly is aerospace metal 3D printing?

Aerospace metal 3D printing means using advanced machines to build metal parts layer by layer, instead of cutting or casting from a big block. It’s like “printing” a metal component, much like a paper printer prints a picture, but carefully building metal in thin layers until the full part is made.

Q2: Why use metal 3D printing instead of traditional methods like casting or machining?

Because metal 3D printing (a kind of metal additive manufacturing) lets engineers design very complex shapes, use less material (so less waste), and build parts faster, even ones that traditional methods can’t make or would take many pieces welded together.

Q3: Can metal 3D printing make parts strong enough for real airplanes and rockets?

Yes. Metal 3D printing can use high-grade metals like titanium or nickel alloys that are strong, heat-resistant, and reliable. These parts meet aerospace standards for strength and safety.

Q4: Does this technology help make parts lighter? Why does that matter?

Definitely, because you build only what you need and can design internal structures (like hollow or lattice shapes), parts can be much lighter. Lightweight parts help airplanes use less fuel and fly more efficiently.

Q5: What kinds of parts can be made with aerospace metal 3D printing?

Many kinds: engine components (like fuel nozzles, turbine blades), structural pieces (brackets, mounts, frames), and even specialized parts for rockets. You can also produce spare or replacement parts on demand.

Q6: Is it faster than traditional manufacturing?

Yes. What used to take weeks or months, casting, machining, welding, and assembling, can sometimes be done in days or a few weeks with metal 3D printing. That helps companies get parts made and planes back in service much sooner.

Q7: Can aerospace companies repair damaged parts using 3D printing instead of replacing the whole part?

Yes, many aerospace companies use certified 3D printing methods to repair damaged components by rebuilding specific areas, reducing waste, cost, and downtime instead of replacing the entire part.

Q8: Are there any cost benefits with metal 3D printing?

There are. Because you waste less metal, skip many assembly steps, and don’t always need expensive tooling or molds, the total cost, especially for complex or low-volume parts, can be lower than traditional methods.

Q9: Are there limitations or challenges to using metal additive manufacturing in aerospace?

Yes. Some challenges include making sure parts meet strict aerospace quality standards, sometimes needing extra finishing or treatment, and handling expensive materials or safety requirements for powders/wires.

Q10: Why do aerospace brands choose FormAlloy for metal 3D printing?

FormAlloy combines certified, aerospace-ready processes (like DED), works with high-performance metals, delivers fast lead times, and offers reliable repair or build-from-scratch capabilities, making it easier for aerospace companies to get flight-ready, mission-critical parts quickly and efficiently.