There’s a metal printer that checks itself while it prints. Sounds cool, right?

Shin, Jeon, and Sohn (2025) figured out how to make it work. They used a kind of printing called DED (Directed Energy Deposition). It’s fast, but sometimes the parts come out wrong—too tall, too short, or just not the right shape.

To fix that, the researchers added a heat camera. It watches the hot, melted metal during printing. If the metal gets too hot, the printer lowers the heat. If it gets too cold, it raises the heat. This camera helps the machine stay perfect as it prints.

It works like a self-correcting oven. No guessing. No stopping. No do-overs. The printer keeps working, layer by layer.

The part that it made came out super-close to perfect. It was only four percent off from the digital design. That is accurate. You don’t have to sand it. You don’t have to reprint it. You don’t waste metal. You get strong, clean parts ready to use.

We appreciate Shin, Jeon, and Sohn for solving this tricky control problem. It helps high-speed laser metal printing stay accurate and reliable.

Now the big question: Why isn’t every factory doing this? Can it make smooth parts, too? Is it better than powder methods? Can it fix broken parts and tools? Can it print airplane or rocket parts? Can it speed up all of the production?

Speed matters today. So, is your shop keeping up?

Boosting Metal Part Throughput Like Never Before

Factories want to print parts faster. Old metal printers take hours or even days. That slows everything down.

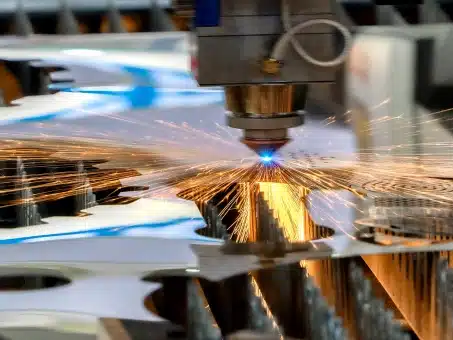

High-speed laser metal printing changes that. It uses a laser to melt metal wire. The machine lays down thick layers fast. You can make large parts in a few hours instead of days.

Yao et al. (2025) tested a new machine with multiple lasers and a coaxial wire feed. They printed with TC11 titanium alloy, a strong metal used in aerospace. They fed wire at 500 mm per minute and moved the laser at 4 mm per second. The result: strong parts, high metal efficiency, and low pollution.

The work by Yao and team shows how clever hardware and tuned settings let printers work fast. They improved the metal structure, increased strength, and cut waste. We thank them for demonstrating real speed gains.

This method shows how high-speed laser metal printing improves throughput. It helps you build more parts and build them faster with no mess and no fuss.

How High-Speed Laser Metal Printing Compares to Powder Bed Fusion

Powder bed fusion spreads fine powder and melts it layer by layer. It makes detailed parts but runs slowly.

The wire-laser method works differently. It skips the powder and uses thick layers. You build big parts much faster. This method suits large jobs better.

A 2025 review by Nagalingam and team studied wire-based DED systems. They compared wire-arc and wire-laser methods. They looked at titanium and aluminum parts used in aerospace. They found that wire methods print large parts faster and with less waste. But they noted those parts still need help to match the precision and smoothness of powder systems.

The study is important, as it offers clear comparisons. If you need speed and size, this method beats powder bed fusion. It may not match tiny details yet, but it delivers fast, big metal parts for real-world needs.

Surface Quality and Resolution—What to Expect

Fast metal printing can leave bumpy surfaces. That may cause parts to look rough or feel uneven. But don’t worry—you can make them smooth.

You can tune settings like laser power, travel speed, and layer spacing. That helps create smoother surfaces and clean edges.

A team at the University of Toronto built a tool called AIDED. It uses machine learning to pick settings in just hours. The parts made with it came out dense and accurate.

The study shows how fast tuning can yield fine quality. It proves that high-speed laser metal printing can deliver smooth, precise surfaces. You just have to use smart tuning.

Why Choose High-Speed Laser Metal Printing for Repair and Cladding Jobs

Metal parts often wear down or break. Fixing them takes time, unless you have the right tool.

High-speed laser metal printing excels at repair and cladding. It builds up metal exactly where needed. It melts just enough material and leaves small, heat-affected zones.

Ebrahim Gholami and Saeed Batebi (2025) tested this with Inconel cladding. They used AI to predict perfect shapes. The result? Clean layers and fast repair jobs.

That’s why this method rocks for repair and cladding. It’s fast, accurate, and doesn’t overheat your part.

Why It Matters for Aerospace Manufacturing

Airplanes need big, strong, and light metal parts. They also need parts built fast, especially during urgent repairs or manufacturing.

This printing method works great for aerospace. It builds large, dense parts quickly. It uses metal efficiently and keeps waste low.

The AIDED study by Shang et al. (2025) showed parts made with over 99.9% density. That’s perfect for aerospace needs.

So yes—this tech is a game-changer for planes, rockets, and even satellites.

Less Waste, More Savings

Old metal printing often wastes metal. Unused powder, support scaffolds, and mistakes create scraps.

High-speed laser metal printing avoids that. It uses wire-fed metal and only prints where needed. You skip supports and powder waste.

In their review article, Li et al. (2022) showed that this method saves metal and cuts waste. The parts are strong, and there’s almost no scrap.

That’s why it’s smart, clean, and budget-friendly.

Why High-Speed Laser Metal Printing Is Key for Big Jobs

Some metal jobs require huge parts, like molds, ship components, or tool dies. Old machines can’t handle that easily or take too long.

High-speed laser printing builds thick layers and avoids size limits. It prints large parts faster, without needing a huge build box.

A new study by Yi et al. (2025) showed that large aluminum and titanium parts built quickly and cleanly.

That’s why it’s the king of large-scale metal work.

Why FormAlloy Rocks at Fast Metal Printing

You need parts that are strong, smooth, and built fast. You also want low waste and easy control.

FormAlloy systems use high-speed laser metal printing to deliver that. We offer smart tuning, strong builds, and flexible job types. We handle aerospace parts, repair jobs, and large-scale builds.

FormAlloy makes your shop faster, cleaner, and more efficient. We bring you speed, quality, and control in one package.

Want stronger parts and faster results? Choose FormAlloy. We’re ready when you are.

FAQs

- What is high-speed laser metal printing?

It’s a fast way to 3D print metal using lasers and wire. You build thick layers quickly. - How does it boost metal part throughput?

It builds large parts in hours with thick layers. That speeds production. - How does it compare to powder bed fusion?

It prints faster, uses less metal, and handles big builds better. - Does it give good surface quality?

Yes. Tune the settings or use smart tools. The result is smooth parts. - Can it be used for repair and cladding jobs?

Yes. It rebuilds worn parts quickly and precisely without overheating. - Why is it important in aerospace?

It builds strong, dense, lightweight parts that meet strict standards. - Does it reduce manufacturing waste?

Yes. It melts only the needed metal and cuts scrap. - How do I optimize print settings?

Use AI tools like AIDED. They pick the best settings fast. - Can it print huge metal parts?

Yes. It’s perfect for large jobs like ship parts or molds. - Why pick FormAlloy systems?

FormAlloy builds smart machines that are fast, precise, and easy to use