A grounded aircraft is an aerospace engineer’s worst nightmare. Every hour that a plane sits on the tarmac, the company loses thousands of dollars. All because a critical metal part needs to be replaced, and ordering a new one could take weeks.

This was a common issue faced by the aerospace industry before high-performance metal 3D printing became a thing. Now, printing a critical part can take as little as a few days.

The urgency does not take away from the strength and durability. And, at the same time, creating lightweight, fuel-efficient parts is much easier with high-performance metal 3D printing.

FormAlloy is one of the leading players in metal 3D printing, helping industries like aerospace, energy, and defense bring their futuristic designs to reality.

Wondering how this revolutionary technology works? You have come to the right place.

What Is High-Performance Metal 3D Printing?

High-performance metal 3D printing is not about manufacturing a part; it is about manufacturing the best possible part, every single time.

What makes it ‘high-performance’ is that it produces extremely strong, precise parts and offers a scalable process.

Unlike traditional manufacturing, high-performance 3D metal printing does not require casting or forging a large block of metal. This is because the process is slow and wasteful, whereas with 3D printing, you can limit waste and achieve more accuracy.

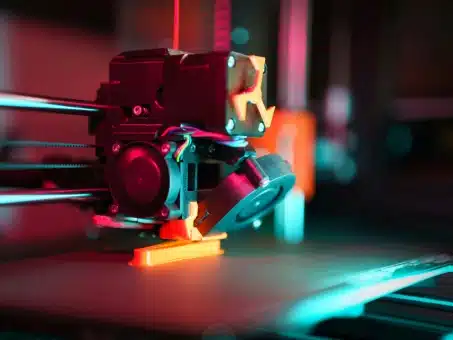

Additive manufacturing, such as Directed Energy Deposition (DED), uses a focused energy source, like a laser, to melt metal powder as it is being deposited. This allows manufacturers to print the part layer by layer, and even repair existing parts with little downtime.

The accuracy and speed you get with high-performance metal 3D printing are unmatched. This is why this technology is so popular in the aerospace industry. It costs less, it’s safer, and it is guided by software that ensures that every detail is perfect.

Why the Aerospace Industry Trusts Metal Advanced Manufacturing

When you think of aerospace, you think about high stakes. Whether it’s fighter jets or spacecraft, every gram of weight and every second of downtime matters.

One of the earliest adopters of metal additive manufacturing applications has been aerospace companies. This is because creating lightweight, durable, and complex components is incredibly valuable for the aerospace industry.

Another way aerospace companies can benefit from additive manufacturing is by producing one-piece designs for testing purposes. The process is less wasteful and cost-effective, making it much more feasible to create experimental designs.

3D metal printing can dramatically reduce downtime, making it possible for manufacturers to print a replacement part on demand, and often right when it’s needed. This means fewer delays, lower costs, and more convenience.

DED vs. Powder Bed Fusion

Not all metal 3D printing is created equal; in fact, choosing the right process can make a huge difference. Let’s compare two of the most popular technologies, DED and Powder Bed Fusion.

Powder Bed Fusion is like baking cookies. You spread a layer of metal powder, and then the laser melts it. This process is repeated until you have a part. The great thing about Powder Bed Fusion is that you can make small, highly detailed parts with incredible accuracy.

Directed Energy Deposition (DED) is more like drawing in 3D space with metal. DED uses a laser to merge metal powder and create complex parts layer by layer. This process allows you to repair damaged parts and build new ones.

You can use both systems, but DED is by far the most effective for aerospace components, industrial tools, and large applications. It offers more precision and allows you to build both small and large parts.

Metal 3D Printing for Part Repair & Refurbishment

One of the reasons why high-performance metal 3D printing is so important to the aerospace industry is its ability to repair and refurbish parts efficiently. In the past, a damaged part could financially drain a company because of how long it took to produce, repair, or replace critical components.

In the present, we have Directed Energy Deposition (DED) to help repair and refurbish components. By depositing metal layer by layer, you can ensure that the parts are as good as new.

Strengthening worn-out parts makes the whole process much more cost-effective. Where a simple crack would ground the plane and cost millions in lost time, now you can have the issue fixed in a few days.

Aircraft companies and manufacturers can use metal 3D printing to repair what they already have. This technology allows the company to save money, reduce downtime, cut costs, and even improve critical systems so that they can run more efficiently.

The Future of High-Performance Metal AM

The metal 3D printing industry is so vast that it has shaped the future of manufacturing as we know it. It has made production smarter, faster, and greener.

You can now expect real-time monitoring to identify and correct issues during the production process. An engineer can ensure that every single part they build meets the exact specifications. The additional focus on sustainability makes metal additive manufacturing such an asset for the aerospace industry.

The goal isn’t just to build parts but to reduce waste, and with high-efficiency metal AM, you can reach a near-zero level of waste.

FormAlloy is one of the leading players in the manufacturing industry, providing advanced systems that rebuild for the future. We are here to help manufacturers achieve their goals.

The future is not years away; it is happening right now, and FormAlloy is spearheading it. If you’re ready to be a part of the revolution, join us.

Call now to learn more about FormAlloy’s fast, efficient, and accessible manufacturing systems.

Frequently Asked Questions

- What is high-performance metal 3D printing?

High-performance metal 3D printing is a manufacturing process that uses advanced technology to create strong, precise, and lighter metal parts for the aerospace, defense, and energy industries.

- What is Directed Energy Deposition?

Directed Energy Deposition (DED) is a process that melts metal powder using a laser to build a complex part, layer by layer.

- How does metal additive manufacturing benefit aerospace applications?

Metal additive manufacturing can benefit aerospace by producing lightweight and durable parts, reducing downtime, and making repairs and refurbishment more efficient.

- What’s the difference between DED and Powder Bed Fusion metal printing?

The difference between DED and powder bed fusion is that DED is better for larger, more complex parts, whereas powder bed fusion is ideal for small, detailed parts.

- Can metal 3D printing repair damaged parts?

Yes, metal printing can help repair damaged sections, strengthen worn-out parts, and rebuild components.

- What industries use metal additive manufacturing?

Metal additive manufacturing is commonly used in aerospace, defense, automotive, and other manufacturing sectors.

- Is metal 3D printing cost-effective?

Yes, metal 3D printing is cost-effective as it reduces material waste and downtime, which could otherwise cost the aircraft companies a lot.

- Can I print with multiple materials in one part?

Yes, you can use multi-material printing to combine materials to create stronger parts.

- How does real-time monitoring improve quality?

Real-time monitoring ensures that each layer is built correctly, so that you don’t have to waste time fixing errors. The product is consistent and provides high-quality results.

- How do I get started with FormAlloy?

You can contact us for a consultation to learn more about FormAlloy’s solutions and to discover what works best for your business needs.