The smell of turbine oil filled the hangar. Cold steel glimmered under bright lights. Elena stood under the big wing, staring at a thin crack in the metal.

That crack had grown overnight. By morning, the airline needed this plane flying again.

In the past, fixing this kind of damage would have taken days. New parts had to be ordered. Crews had to take the pieces apart. The plane would sit, losing the airline money.

This time was different. The crew rolled out a laser directed energy deposition (DED) machine. The laser shone a bright path, melting new metal right into the damaged spot. Bit by bit, the crack disappeared. The surface looked new again.

That night, Elena learned something important: the best laser systems for metal deposition do much more than fix damage. They save time. They reduce waste. Most of all, they help keep planes safe in the air.

And in aviation, the stakes have never been higher.

How Does Laser Deposition Work?

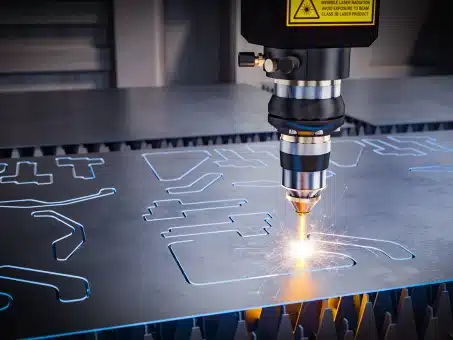

Laser metal deposition (LMD)—sometimes called laser-directed energy deposition (L-DED)—is like using a super-precise welding machine.

A strong laser heats the surface of a part until it melts slightly. At the same time, new metal is added. This metal can be powder or a solid wire. The melted material blends with the base part and hardens into a strong, smooth surface.

The laser follows a very exact path, guided by a computer. It can rebuild worn edges, restore missing shapes, or even make brand-new layers on an existing part.

In their 2020 review, Zhong et al. studied LMD with Ti-6Al-4V, a titanium alloy used in many airplane parts. They tested how different laser settings—like power and travel speed—changed the way the metal cooled and formed. They found that, when done right, parts made this way could be just as strong as parts made in a factory.

They also looked at the tiny structures inside the repaired metal. Good heat treatment after the repair made these structures more even, which helps the part last longer under stress. For airplanes, this is critical. Every flight puts parts under huge pressure.

The lesson? LMD works for aviation, but only if the laser settings are exact and the repairs are done with care.

Why Powder-Fed Systems Matter

In a powder-fed LMD system, fine metal particles are blown into the melt pool with a special gas.

It lets engineers control the exact mix of metals being added. It’s perfect for thin coatings, small repairs, or special finishes on expensive airplane parts. Titanium alloys like Ti-6Al-4V work well this way because they’re light but strong.

A recent study by Lv et al. (2023) used special high-speed cameras to watch what happens to powder particles under the laser. They saw tiny pieces flying, melting, and clumping together. They tested different laser powers and found that too much power made the flow unstable, which could lead to defects.

For airplanes, even small surface flaws can be dangerous. That’s why understanding how powder behaves in the laser beam is so important. Powder-fed systems are powerful, but only if the flow is smooth and the settings are right.

How Do Wire-Fed Systems Work

Wire-fed DED uses a solid metal wire instead of powder. The wire is fed right into the melt pool, melting instantly and bonding with the part.

This method works fast. It can add a lot of metal in a short time. And because all the wire is used, there’s almost no waste. It also makes the work area cleaner, with fewer airborne particles than powder-fed systems.

In their 2022 study, Smoqi et al. tested a new closed-loop control system for wire-fed DED. They used sensors to watch the melt pool’s temperature in real time. The system adjusted the laser power automatically to keep the temperature steady.

The results were clear: parts made this way had fewer air bubbles (porosity) and more even metal structures. Without this control, the parts had mixed structures and uneven hardness. For airplanes, this stability means the part will be safer and last longer.

Wire-fed systems are especially good for big repairs on large parts—like wing sections or landing gear components—where speed and strong bonding are both critical.

Why Titanium Alloys Matter

Airplanes need materials that are strong but light. Titanium alloys—especially Ti-6Al-4V—are perfect for this. They also resist rust and damage from weather.

But repairing titanium with lasers isn’t easy. The heat has to be just right. If it cools too fast or too slow, the metal can form brittle spots. Even tiny flaws can cause cracks over time.

In their peer-reviewed study, Ren et al. (2019) showed that when LMD repairs are done with the right heat and atmosphere, titanium parts can be just as strong as the originals. But if the process isn’t controlled well, the part can become weak.

For aviation, that’s a risk no one can take. That’s why the best laser systems have features to keep heat and cooling perfectly balanced.

How to Choose System Features

The right laser system depends on the repair job.

For small, precise work, choose a powder-fed system. For big builds and quick turnarounds, go with wire-fed.

No matter the type, look for:

- Closed-loop controls to watch and adjust the melt pool in real time

- Multi-axis movement so the laser can reach every angle

- Switchable powder/wire heads for flexibility

Wang et al. (2024) found that systems with thermal control could keep the melt pool steady, avoiding warping and oxidation. For hangar work, it’s also important to have portable machines with good debris control.

Why Precision Matters in Aviation

Airplanes go through thousands of pressure changes in their lifetime. Even the smallest mistake in a repair can shorten the part’s life.

Laser systems that control every layer’s shape and bonding make parts safer. They also mean fewer scrapped parts, faster repairs, and better use of expensive materials.

For maintenance teams, this is everything. It means they can fix planes quickly without sacrificing safety.

Fix Faster, Fly Safer

Elena’s late-night repair showed what’s possible when the right tools are in the hangar.

The best laser systems for metal deposition aren’t just advanced—they’re exact. Powder-fed systems give fine control. Wire-fed systems bring speed and strength. Titanium expertise ensures repairs last. Closed-loop controls keep every layer perfect.

This is where FormAlloy stands apart. Our systems combine both powder and wire capability in one machine, with built-in closed-loop control and proven aerospace performance. That means one platform can handle delicate coatings, bulk builds, and complex titanium work, without compromising quality.

In aviation, there’s no room for error. With FormAlloy, you get faster turnarounds, lower scrap, and the confidence that every repair meets the toughest airworthiness standards.

Don’t settle for less. Bring FormAlloy into your maintenance operation and keep your fleet safer, faster, and in the air where it belongs.

FAQs

Q1: What is laser metal deposition?

It’s a way to repair or build parts by melting the surface with a laser and adding new metal.

Q2: Which feed system suits which job?

Powder-fed for fine control; wire-fed for speed and low waste.

Q3: Can LMD fix critical aircraft parts?

Yes, if the process is approved and inspected.

Q4: Does it work on titanium parts?

Yes, especially Ti-6Al-4V, if the heat and atmosphere are controlled.

Q5: Which systems reduce errors best?

Systems with sensors that adjust the melt pool in real time.

Q6: Are there cost benefits?

Yes, less scrap, faster repairs, and less downtime.

Q7: Is powder feeding risky?

It needs safety measures to handle fine powders.

Q8: How long do repairs take?

Often just hours, not days.

Q9: Will regulators approve repaired parts?

Yes, if repairs meet testing and documentation rules.

Q10: How to choose a provider?

Pick one with proven aerospace results, closed-loop controls, and flexible feed options.