Have you ever seen a robot build something out of metal? What if it could print metal just like a 3D printer makes toys? That is what Directed Energy Deposition (DED) does. But what is DED? How does it work? Can it fix airplane parts? Can it save time and money?

These are big questions.

Many people know DED can help build and fix metal parts. But they don’t talk about the small problems it brings. They also don’t mention some cool benefits that can help industries a lot.

So, are there hidden pros and cons of DED? Can this technology change how we build in the future?

Let’s find out.

What Is Directed Energy Deposition and How Does It Work?

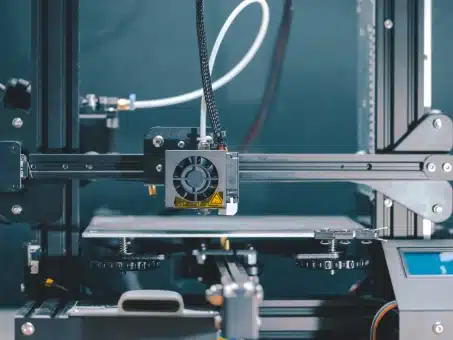

Directed Energy Deposition (DED) uses lasers to melt metal. It adds metal layer by layer. This builds up a 3D shape. Metal can come in the form of powder or wire.

DED is great for fixing broken parts. It is also used to make new parts. Many industries use DED because it is fast and flexible.

DED Is Good for Repairs

A recent study by Blaha et al. (2024) found that DED works well for fixing jet parts.

The study showed that the inside of the part stayed strong after repair. It helps the part last longer.

So, one big advantage of DED is its repair power.

How Does Directed Energy Deposition Compare to Powder Bed Fusion?

DED and Powder Bed Fusion (PBF) are both metal printing methods. But they work differently.

DED adds metal while the head moves. PBF uses a flat bed of powder. A laser melts it one layer at a time.

DED Builds Bigger Parts Faster

A 2025 study compared DED and Powder Bed Fusion for Ti-6Al-4V alloy prints.

It found DED builds parts up to ten times faster and handles larger sizes.

So, a hidden advantage is that DED saves time on large jobs.

What Materials Can Be Used in Directed Energy Deposition?

DED can use many metals. These include titanium, steel, aluminum, and Inconel.

You can even use more than one metal in one part. That means you can make parts stronger in some places and lighter in others.

You Can Mix Metals in One Part

In 2025, a group of scientists from National Engineering Laboratory of Advanced Manufacturing for Large Metallic Components, led by Yaru Liu, printed a titanium–TC25G gradient alloy using laser DED (L-DED). This peer-reviewed study shows DED’s capability to produce multi-metal gradient components.

This is a cool advantage of DED you don’t hear about often.

What Industries Benefit Most from Directed Energy Deposition?

DED is used in many industries:

- Aerospace (planes)

- Energy (pipes and turbines)

- Defense (military tools)

- Racing cars (custom metal parts)

These industries like DED because they need fast, strong repairs.

DED Saves Time and Money

A 2024 open-access study by Stéphane Touzé et al. showed a closed-loop controlled DED repair process for stainless steel and Inconel. It reported greatly improved build accuracy and reduced defects during repair.

It serves as a big advantage when thinking about the pros and cons of DED.

What Are the Limitations of Directed Energy Deposition Technology?

Not everything about DED is perfect. Sometimes the parts it prints are a little rough. They need to be cleaned or shaped after printing.

Surface Can Be Rough

A 2024 peer-reviewed study on DED surface roughness showed roughness values ranging from 3.2 µm to 42.9 µm on Inconel 718 builds, depending on process settings. It highlights how scans can leave bumps. Post-processing like grinding or polishing adds time.

So, a disadvantage is that DED parts often need extra work.

Can Directed Energy Deposition Replace Traditional Machining?

DED builds the basic shape fast. But the final shape often needs cutting or polishing.

DED and Machining Work Best Together

A 2025 study published in Applied Sciences on hybrid manufacturing using DED and CNC milling showed that combining both methods improved surface finish and reduced total manufacturing time by over 60%.

However, the process still needed milling for fine details and surface smoothness.

So, while DED is fast, it cannot fully replace traditional machining yet.

How Precise Is Directed Energy Deposition for Metal Repair?

DED can fix metal parts very closely. But it needs good tools and smart software.

Precision Needs Control

A 2025 study published in Advanced Manufacturing tested closed-loop melt-pool height control using thermal imaging in DED. The researchers found that real-time feedback greatly improved the accuracy and shape of printed parts.

Without control, errors happen. With FormAlloy’s DEDsmart®, precision gets better.

So, smart tools turn a disadvantage into an advantage.

Why Is Directed Energy Deposition Considered for Hybrid Manufacturing?

Hybrid means using DED and machining together. DED builds the shape. Machining gives it a smooth finish.

Hybrid Is Super Efficient

A 2024 review by Haley et al. in the Journal of Manufacturing Process reported that hybrid DED and machining processes reduced total manufacturing time by 68%, and cut material costs by 97% compared to traditional CNC-only workflows.

This combo gives the best of both worlds.

So, another advantage is that DED works well in hybrid systems.

Is Directed Energy Deposition Cost-Effective for Aerospace Applications?

Aerospace companies love DED because it cuts waste. It also fixes expensive parts instead of throwing them away.

DED Saves Money Over Time

A 2024 study by Khanna et al. provided a detailed cost model for DED. It showed DED dramatically reduces waste and production overhead compared to Powder Bed Fusion.

It saves time, materials, and energy.

So, a hidden advantage is that DED helps big industries save big money.

What Are the Future Trends in Directed Energy Deposition Technology?

The future of DED looks smart. New systems can watch and fix errors as they print.

AI Makes DED Smarter

A comprehensive review by engineers and materials scientists at Ningxia University showed real-time monitoring cut defect rates by 70% in wire-arc DED experiments.

FormAlloy already uses DEDsmart® to help with this.

The future is bright, and this is a big advantage of DED.

Why FormAlloy Leads the Way

FormAlloy makes DED smarter. Their DEDsmart® software watches every layer. It shows the melt pool, laser power, and shape in real time.

It helps builders fix problems fast. It allows parts to come out just right. No other system offers this much control.

FormAlloy makes DED smarter, safer, and better.

Want to see better builds and faster results? Choose FormAlloy.

FAQs

- What is Directed Energy Deposition used for?

DED is used to make or fix metal parts. - What metals can DED use?

It works with titanium, steel, aluminum, and more. - Is DED better than machining?

DED is faster for building, but still needs machining to finish. - Can DED fix airplane parts?

Yes, DED repairs parts like blades and nozzles. - Does DED save money?

Yes, it reduces waste and repair costs. - Is DED good for big parts?

Yes, it prints large metal parts faster than other methods. - Can DED be used in cars?

Yes, race cars use DED for special parts. - Is the surface smooth after DED?

No, most parts need polishing or cutting after. - What makes FormAlloy special?

They use smart tools like DEDsmart® to control every build. - What’s next for DED?

Smarter systems and more metal types are coming soon.